Four-side Sealing Kraft Paper Bag Napkin Packaging Machine

- Model:

- LD-FP300

- MOQ:

- 1 set

- Payment:

- L/C,T/T

- Place of Origin:

- China

- Brand:

- LEAD

- Delivery Time:

- 7-20 days

Paper bag packaging machine for paper napkin

This kraft paper bag machine use pure paper roll to form a bag, automatic product filling in the bag, glue seal and cut to a 4 side paper bag.

Technical Features

1. Panasonic PLC, Delta servo motor driving system can ensure more intelligent and stable performance.

2. The parts touching products are made of stainless steel 304.

3. Bag length can be preset on the touch screen. Automatic counting number can be preset.

4. The photoelectric sensor make edge correction. It can align paper edge.

5. Automatic feeding system can fulfil 3-8 pieces of different products in a package.

6. The whole automatic paper packing machine is up to 150 bags/min.

7. The puncture device can poke small pinhole on the paper to exhaust air in the bag. It can save space for next step bulk package.

8. The date printer is ink roll type for 3 lines manufacturing date, expired date, batch No.

9. After package, automatic counting conveyor can make a gap between preset quantity packages. It’s convenient to repack in carton box.

The advantages of 4 side sealing bag packing machine

Packaging is a necessary condition for products to enter the circulation field, and the main means to achieve packaging is to use kraft paper bag packaging machinery. With the development of the times and the advancement of technology, packaging equipment is playing an increasingly important role in the packaging field. Its main functions are as follows:

(1) It can reduce labor intensity and improve working conditions

Hand-made bags are labor intensive, consume energy, and have low efficiency. For light and small products, due to the high frequency and monotonous movements, workers are likely to get occupational diseases.

(2) Can reduce costs

Manual bag-making errors and reject rates are relatively high, there are more unqualified bags, and more raw materials are wasted. The mechanical bag making can minimize the scope of waste products and reduce the waste of raw materials.

(3) It can greatly improve labor productivity

For example, kraft paper bag, manual bag making can only be 1 or less per minute, while paper bag making machine every time Up to 150 per minute per minute, which improves the efficiency hundreds of times.

(4) Can effectively guarantee the quality of paper bags

Mechanical packaging can produce paper bags with consistent specifications according to the required shape and size according to the requirements of paper bags, but manual bag making cannot be guaranteed. This is particularly important for export commodities. Only paper bag sealing machine can achieve the standardization and standardization of packaging and meet the requirements of collective packaging.

Technical Parameter

| Item | LD-FP300 Automatic paper bag packaging machine |

| Paper roll | Pure paper laminated glue |

| Paper roll size | 300mm wide / 60gr -140gr thickness |

| Bag Size | (L)60-300mm (W)65-100mm(H) 10-40mm |

| Packing Capacity | 60-100 bpm |

| Power | 220V, AC 220V 50/60HZ, Total 6.8KW |

| Dimension | Napkin machine 1.97*1.62*1.8M Conveyor 1.0*0.57*0.55M Packing machine 3.0*0.97*1.65M |

| Machine weight | 2000Kgs |

Product Application

High speed fully automatic paper bag making machine.A variety of specifications. Our products are deeply loved by customers at home and abroad. Certificate Complete. Variety of Products.

Factory Direct Sales. Quality Assurance.The paper bag packaging machine is suitable for packing paper bag, multi-ply paper bag and inner plastic layers.

|

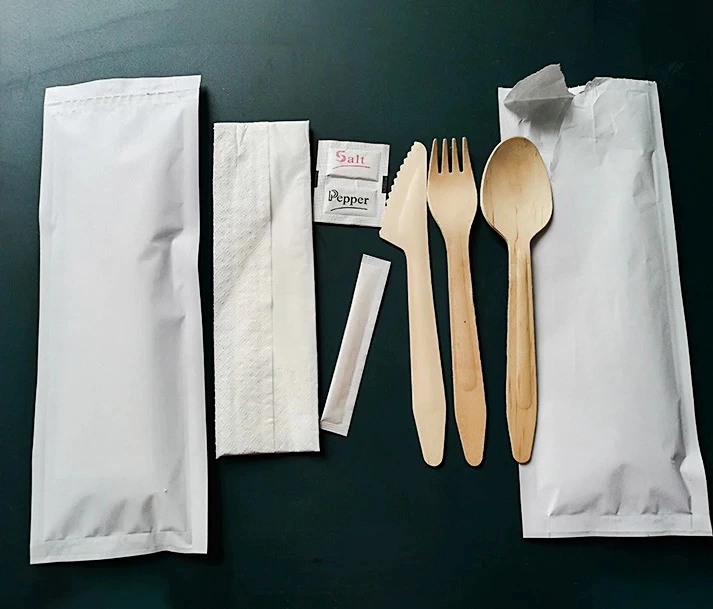

Biodegredable cutlery paper bag packaging machine |

Wooden cutlery paper bag packaging machine |

Tissue cutlery paper bag packaging machine |

Tissue paper bag packaging machine |