About Automatic Pillow Packaging Machine

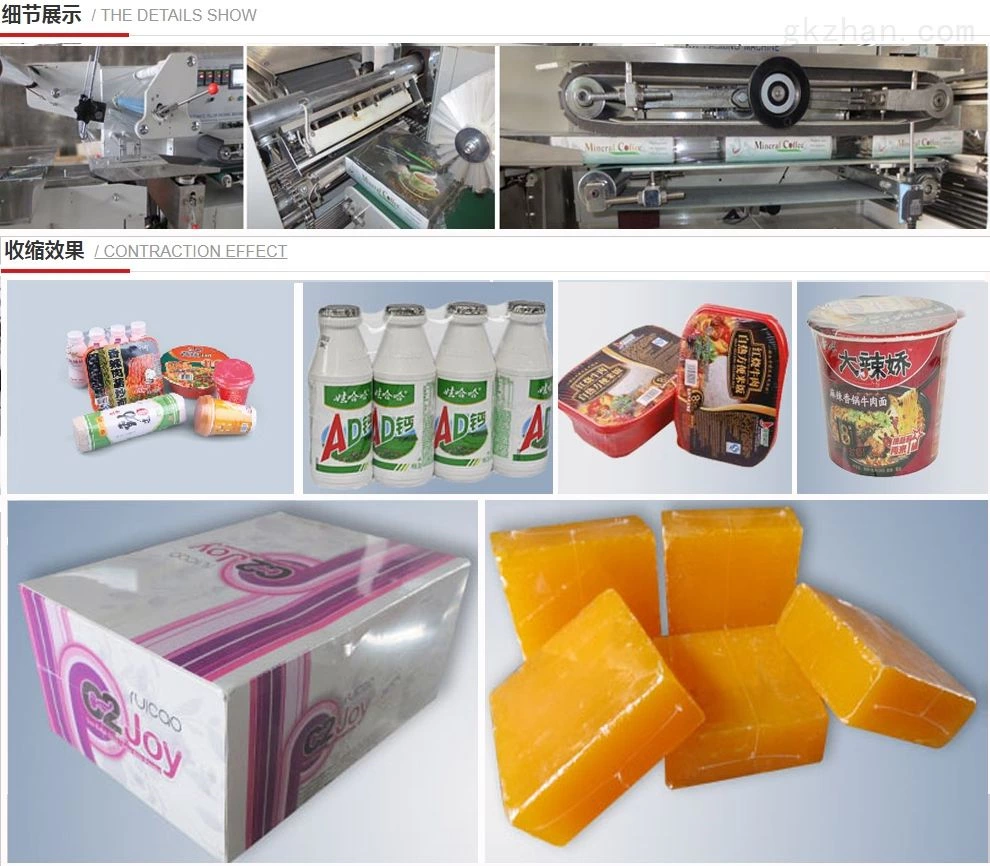

The automatic pillow packaging machine is an automatic continuous shrink packaging equipment. Using quartz far-infrared tube heating, energy saving and high efficiency (more than 15% power saving); shrinkage temperature and motor transmission speed are stable and adjustable, and the adjustable range is wide; the original drum rotation device can work continuously. It is specially designed for the packaging of various solid and regular objects, and is widely used in food, dailynecessities and industrial parts, etc.

The operation of the variable frequency stepless speed regulation motor of the automatic pillow packaging machine is driven by the V-belt to drive the tooth chain stepless transmission. The planetary differential mechanism can adjust the conveying length of the paper film, and the output shaft of the gear box drives the paper film pressing roller to rotate and convey the paper film through the chain drive. And in the packaging process using photoelectric tracking color code monitoring. At the same time, the gear box is also driven by multiple sets of chains to realize the packaging of items. Movement of conveyor belt, paper puller, pressure roller, horizontal sealing knife and finished product conveyor belt.

Main feature

1) The structure is compact and reasonable, the performance is stable and advanced, and the operation is simple and easy to understand.

2) Double frequency conversion control, stepless speed change, the bag length can be set and cut immediately, no need to adjust the idling, it can be completed in one step, saving time and film.

3) Using internationally renowned electrical components, PLC control, touch-type man-machine interface, parameter setting is convenient and quick.

4) The fault diagnosis prompt is clear at a glance, and the use is more user-friendly.

5) High-sensitivity electric eye color tracking makes the sealing position more accurate.

6) The PID temperature is adjustable, suitable for color filters of various materials, to improve the sealing quality.

7) It has the function of positioning and stopping, and it does not stick to the knife and does not cost the film.

8) The transmission system is concise and clear, the work is more reliable, and the maintenance is more convenient.

9) All controls are realized by software, which is convenient for function adjustment and technical upgrade, and can adapt to the production needs of different periods

10) Automatic feeding of medicine plates, suitable for automatic feeding of various specifications of aluminum-plastic medicine plates