About letterpress printing presses

About letterpress printing presses

What is a letterpress printing press:

Letterpress printing machine, also known as flexographic printing, because letterpress printing uses flexible materials (usually

Refers to the printing of resin plate materials). The letterpress paper cup printing machine is the contact between the soft rubber roller and the hard printing plate. As long as you see the printing plate with the graphic part obviously higher than the blank part, (such as movable type, stereotype, etc.) this is basically letterpress printing.

The development history of letterpress printing press:

In 1812, Koenig in Germany made the first circular flattened letterpress and curved offset printing machine; in 1847, Hoy in the United States invented the rotary printing machine; in 1900, it made a six-color rotary printing machine; in 1904, the United States Rubell invented the offset printing press.

Before the 1950s, the traditional letterpress printing process dominated the printing industry, and the development of printing machines was also dominated by letterpress printing machines. However, the lead alloy letterpress printing process has the disadvantages of high labor intensity, long production cycle and environmental pollution. Since the 1960s, the lithographic offset printing process with the characteristics of short cycle and high productivity began to rise and develop, and lead alloy letterpress printing was gradually replaced by lithographic offset printing. Soft letterpress printing, stencil printing, electrostatic printing, inkjet printing, etc., have also been developed in packaging printing and advertising printing.

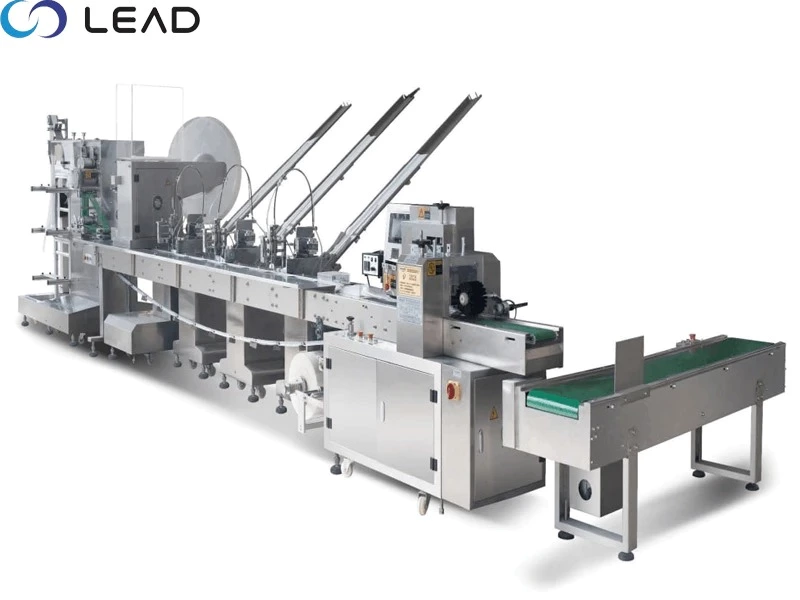

Introduction of six functional features of cup printing machine, bowl printing machine and box printing machine (curved offset printing machine)

1. Using automatic cup feeding and automatic cup stacking equipment, cup stacking is more accurate.

2. All adjustments are placed outside, making the operations more user-friendly.

3. It has a precise ink temperature and quantity control system and a "no cup, no printing" operating system.

4. The application of corona treatment makes the printing process more scientific.

5. It has an efficient UV curing system, which makes the ink dry faster and more firmly.

6. The most advanced monitor is used for PLC electronic control and digital display function system, which makes the operation conversion of the machine more efficient.

Ruian Lead Machinery & Technology Co., Ltd., is a modern automatic packaging machine factory, manufacturer in the automatic packaging machinery industry. Lead Machinery's cup printing machine and flexo printing machine are stable in performance and reliable in quality. Our cup printing machine including paper cup printing machine, foam cup printing machine and plastic cup printing machine.They are characterized by the following advantages: high precision, high efficiency, high flexibility, low abrasion, etc. They can be widely used in different fields.Want to know cup printing machine price? Call us.