About Shrink Wrapping Machines

Heat shrinking machine, also known as side seal shrink wrap machine and shrink wrapping machine, is one of the more advanced packaging methods in the market. It uses shrink film to wrap the product or package outside, and heats the shrink film to wrap the product or package tightly to fully display the appearance of the item. Improve product exhibition and sales, increase aesthetics and sense of value. At the same time, the packaged items can be sealed, moisture-proof, and pollution-proof, and protect the goods from external impacts, and have a certain degree of cushioning, especially when packaging fragile items, it can prevent containers from flying when they are broken.

In addition to its own advantages, it can also reduce the possibility of product being disassembled and stolen; it is suitable for tight packaging and pallet packaging of multiple items. Heat shrinking machines are widely used in the packaging of glass bottles, styrofoam, cartons, toys, electronics, electrical appliances, stationery, books, records, hardware tools, daily necessities, cosmetics, beverages, fruits, commemorative labels, etc.

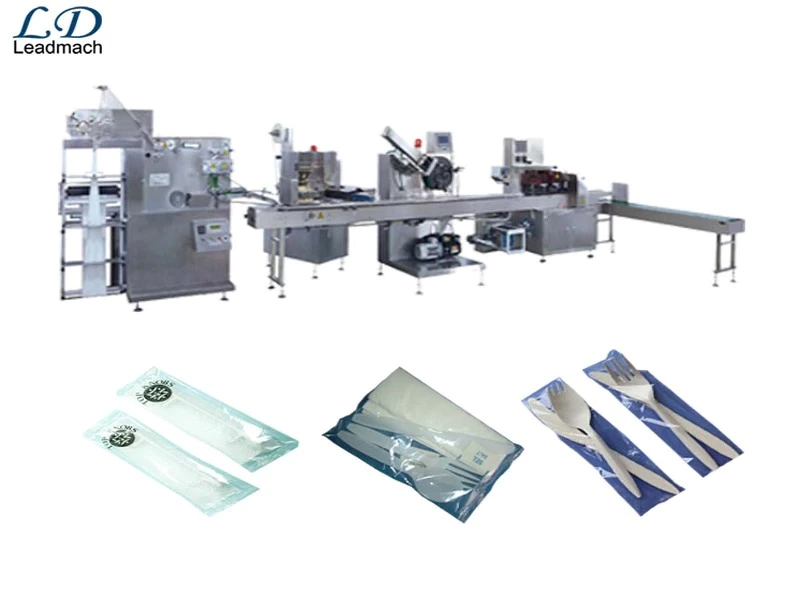

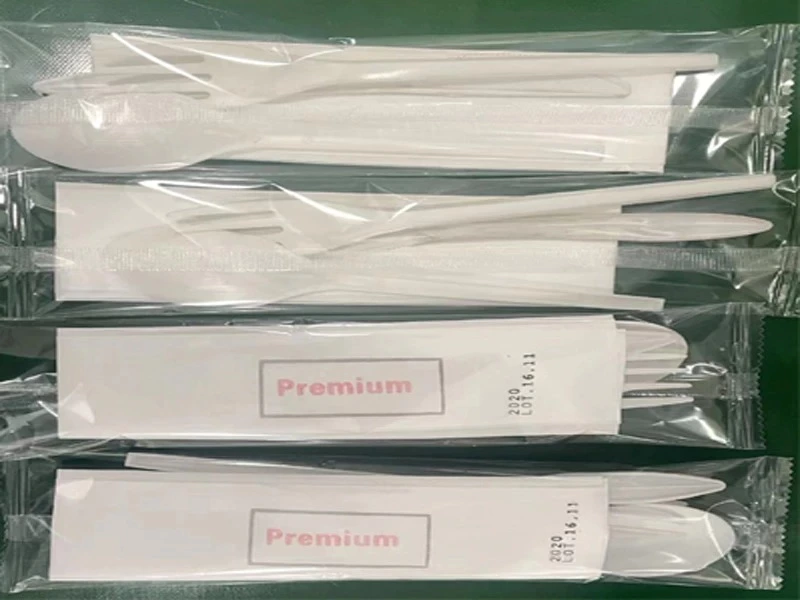

There is also a best shrink wrap machine for food (tableware packaging machine), which is specially used for heat shrinking of tableware. This tableware shrinking machine equipment is especially suitable for large-scale packaging in industries such as catering tableware, software, printed matter, biscuits, pharmaceuticals, ceramics, beverages and flooring. Batch shrink film packaging.

Advantages of heat shrinking machine:

① Using far infrared direct heating;

② The equipment is compact in size, with short warm-up time and power saving;

③ Electronic stepless temperature regulation;

④ Shrinkage does not affect the quality of the packaged items and can shrink the package perfectly;

⑤ Applicable to the packaging of regular or irregular items ;

⑥Automatic shutdown function, when the furnace temperature rises to the specified temperature, the equipment will automatically cut off the power supply, saving the cooling time and ensuring the normal service life of the equipment.

Functions of heat shrink packaging machine:

The heat shrinkable packaging machine has the fully automatic function of conveying and feeding, wrapping film, sealing and cutting, shrinking, cooling and shaping. The heat shrinking machine adopts film constant temperature heat sealing technology, and the seal is clear and firm. The sealing rapid cooling structure ensures higher sealing strength under high-speed production conditions. The automatic cycle control of the program is adopted, and the performance is stable and reliable. The original imported guide rod cylinder ensures precise movement. Durable. The sensor switch controls the film feeding system, which can reliably control the length of the film feeding and reduce the loss. All transmission is frequency conversion speed regulation, and the transmission is smooth and smooth. Unique heat shrink channel, two sets of centrifugal hot air circulation system, even heat balance, shrink tight, beautiful. Three-layer heat insulation treatment, good heat preservation performance, fast heating and energy saving. Enhanced cooling and shaping channel, the packaging film can quickly become a high-strength state, which is convenient for storage and transportation. It is easy to adjust when the packaging combination and bottle type are changed, and it can realize the multi-purpose function of one machine.