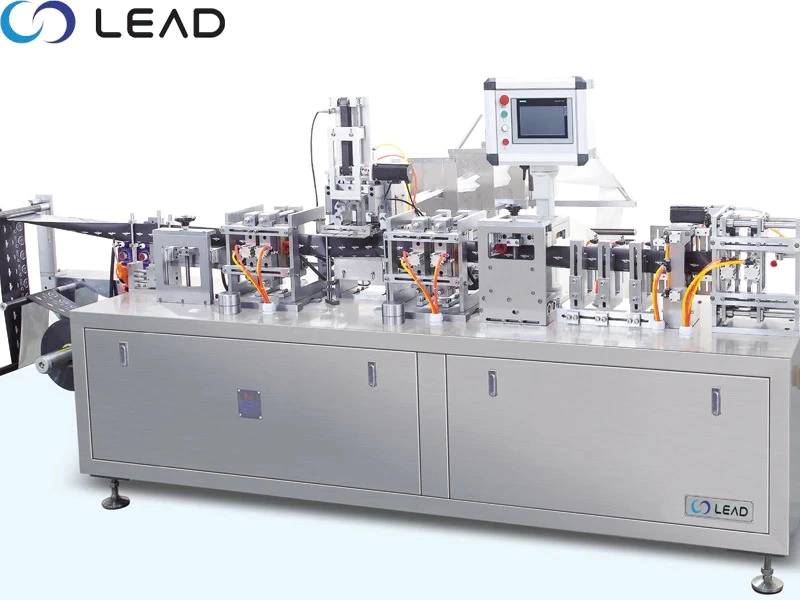

Application of tableware packaging machine

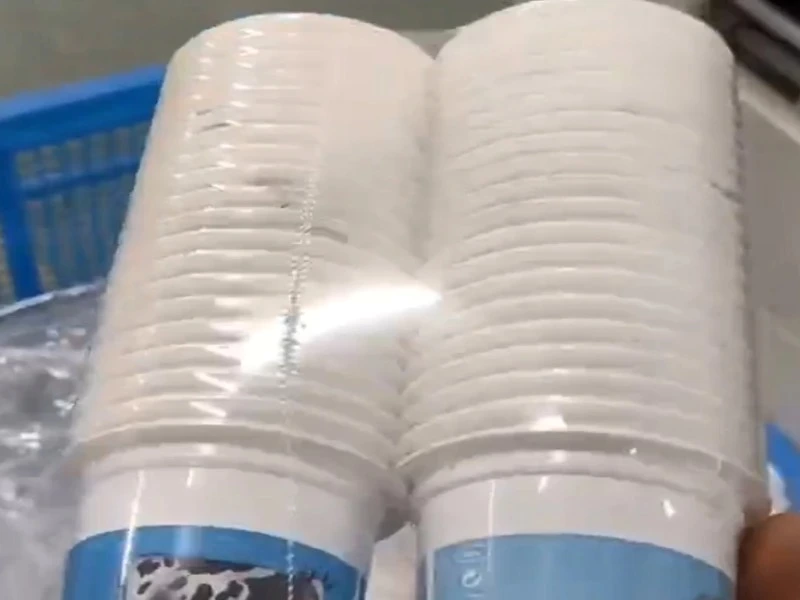

The use of tableware packaging machine can improve productivity, reduce labor intensity, meet the needs of large-scale production, and improve the requirements of cleanliness.

The tableware packaging machine process includes the main procedures such as filling, packaging and sealing, as well as related front and rear processes such as cleaning, stacking and disassembly. In addition, cutlery packaging machines include processes such as dosing or stamping the packaging.

What is the reason why the tableware packing machine heats up slowly or fails to rise to higher temperatures (above 160 degrees Celsius)?

1. The wiring of the heater is that the main power line passes through a magnetic switch and then goes to the electric heating tube, so first check whether the contacts of the magnetic switch are normal. This phenomenon occurs if the line does not pass through one of the phases.

2. If the magnetic switch is normal, check the appearance again to see if the ohm value is the same. If all phases are connected, but the circuit or electric heating tube is still abnormal, the tableware wrapping machine needs to replace the heater.

The food packaging machine is a kind of packaging equipment that we commonly use. Before using it, we need to clearly understand this equipment, and then its structure and operation method, so that we can understand the working principle of the automatic packaging machine.

The best automatic packaging equipment adopts positioning sealing and cutting during the packaging process. In packaging production, due to the positioning errors printed on the packaging material, due to the influence of factors such as material stretching and mechanical transmission, the predetermined sealing and cutting positions on the packaging material may deviate from the correct position, thereby causing errors.

In order to eliminate errors and achieve correct sealing and cutting purposes, automatic packaging machines must consider the problem of automatic positioning

The positioning mark completes the design of the continuous photoelectric automatic positioning system. According to the working mode of complementary error, the continuous photoelectric positioning system is divided into advance and retreat type, braking type and dual-drive system synchronous type.

With the continuous development of the cutlery packaging machine equipment industry, the tableware packaging machine is a good packaging machine product, which combines pneumatic components and mechanical devices. Such tableware packaging machine equipment is made of high-quality materials, the production process is very advanced, the performance is very superior, and the use effect is also very obvious. The tableware packaging machine has a very wide range of applications and can be used in many industries.

The cutlery machine is produced and designed in accordance with the corresponding national standards and requirements during production, which can reduce labor costs and make the product more beautiful and atmospheric, which is of epoch-making significance. Carry out maintenance and maintenance, which will make the service life of the tableware packaging machine equipment longer. Such products can be classified into many different categories, including semi-automatic tableware packaging machines and fully automatic cutlery packing machines according to different application properties, as well as the type of napkin cutlery packing machine production line.