Automatic cup printing machine manufactuer

Plastic cups offer your customers an affordable and efficient way to market their brand at an event or meeting.

When you are looking at tooling to use for placing your plastic cups on prior to printing, it is important to make sure the tolerance for the sizes of cups you receive are made known by the manufacturer for your machine. You need your plastic cup to be hugging the fixture it is placed on for optimal prints and avoid any tooling that will affect the form of the plastic cup when the screen is moved down and the squeegee pushes the ink through the screen on the part. If there is space for the cup to bend, your image will be compromised. Lead Machinery offers precision manufacturing and we will show you that the paper cup printing machine price works prior to shipping through test print videos using your product

Plastic cups range in their thickness. If you are using a thin plastic cup that is typically used for parties and one time uses, it is advised you do not use forced hot air to cure your products to avoid any warping that may occur. Conventional UV curing may also cause warping but this can be mitigated by opting for UV LED. Lead Machinery systems that use conventional UV are designed with your ability to control the amount of UV that your cup is exposed to and the time it is exposed for. We will work with you on finding the process best for your product.

WHY UPGRADE YOUR SCREEN PRINTING MACHINE FOR YOUR PLASTIC CUPS?

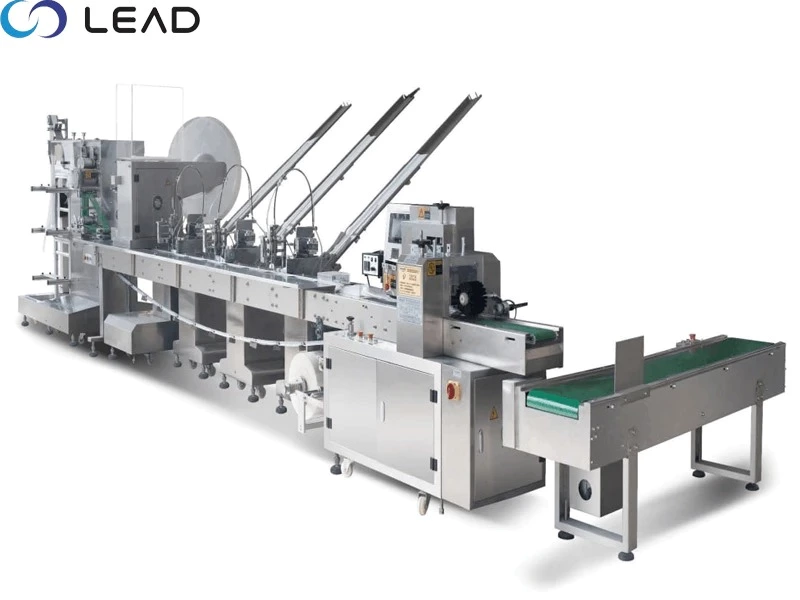

Lead Machinery offers plastic cup screen printing machines for new printing businesses to established shops looking to upgrade their machines.

This foam cup printing machine is perfect for the new and experienced printers alike. Tooling for plastic cups is simple and affordable. Swapping mandrels on your tooling fixture takes seconds and can't get any easier. Mechanical and optical sensors are available for multi-color registration.

Mechanical and optical registration are available depending on your cup type and means in which we register. Typically plastic cups can be molded to include a notch on the bottom that will provide a means of registration for multi-color prints. Optical registration may be used for registering the product based on color identification.