Common fault inspection and troubleshooting methods of tableware packaging machine(One)

After the machine has been running for a long time, there will be some minor problems or operational problems. Now let us take a look at the common fault inspection and troubleshooting methods of the tableware packing machine

Firstly. The power indicator light is off:

1. No power supply 1. Check whether the power supply is connected

2. The indicator light is damaged. 2. Replace the power indicator light

Secondly. Leakage switch tripping:

1. Machine leakage 1. Check whether the tableware packaging machine has leakage (horizontal seal heater, motor solid state relay, fan.

2. The components are damaged. 2. Check whether the leakage switch is damaged.

Thirdly. Temperature control failure

1. No heating 1. Replace the heating plate or solid state relay, temperature control module

2. The temperature cannot be detected 2. Replace the thermocouple or temperature control module

3. The temperature continues to rise 3. Replace the solid state or temperature control module

4. The temperature fluctuates greatly 4. Replace the thermocouple or temperature control module

Forthly. The host cannot be started (motion controller)

1. Emergency stop switch light 1. Check whether the emergency stop switch is blocked and whether the signal is disconnected

2. Whether the servo motor is overloaded 2. Check whether the load of the servo motor is too large (see parameters for details)

3. The motion controller is faulty. 3. Check whether the RUN indicator light of the motion controller is normal, and whether the POWER indicator light is alarming.

4. The start button is faulty 4. Replace the start button

Fifthly. Poor horizontal seal

1. Improper temperature adjustment 1. Adjust the temperature according to the packaging material and speed

2. Improper adjustment of the horizontal sealing machine 2. Adjust the eccentricity with reference to the horizontal side seal shrink wrap machine

3. The quality of the packaging film is too poor 3. Replace the high-quality packaging film

4. The heater is not hot. 4. Check the horizontal sealing heating solid state relay, replace the thermocouple and heating plate

5. packing film constantly. 5. If the spring pressure is insufficient, adjust the pressure, adjust the temperature, and readjust the cutter. If the cutter is deformed, replace the cutter.

6. The packaging film sticks to the knife. 6. If the temperature is too high or the cutter has been running for a long time, there are foreign objects, which should be removed with a brush in time.

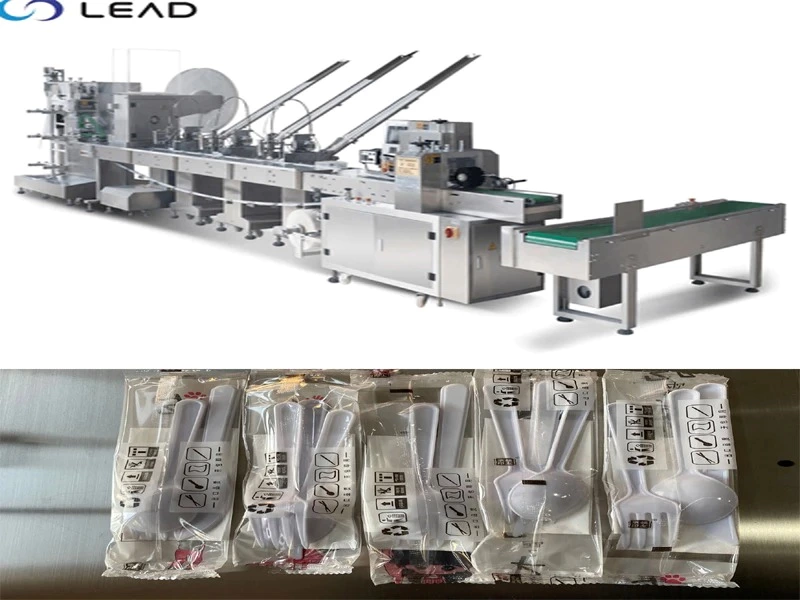

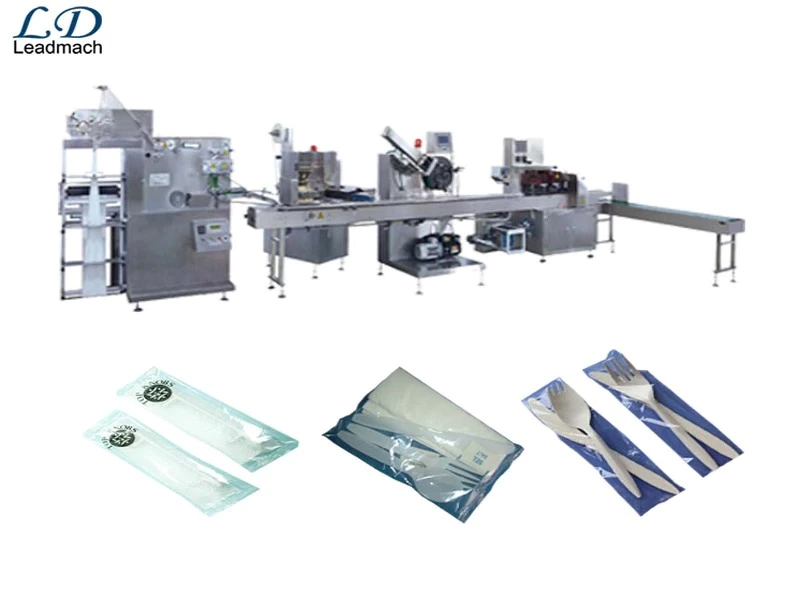

Lead Machinery is a professional manufacturer of cutlery packaging machines. We provide customers with 24-hour technical services. Whether it is an operational problem or a machine failure, we will solve it for customers as soon as possible.Buy packaging machinery, contact us, buy the best quality china biodegradable tableware machine with the most affordable price.