Correct operation and daily maintenance of automatic packaging machine

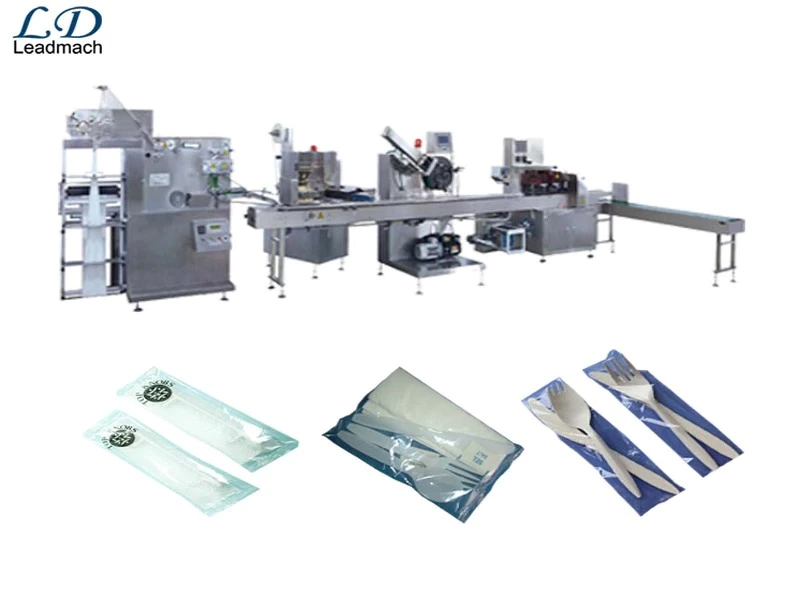

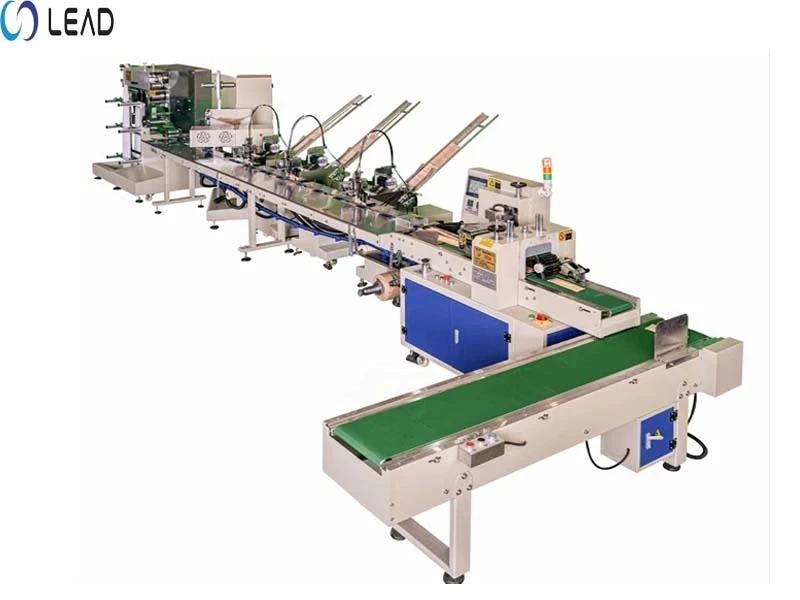

Labor costs are getting higher and higher, and it is an inevitable trend for mechanized operations to replace manual labor. For some heavy packaging work, many companies choose to replace manual labor with fully automatic packaging machines. Although the equipment has many advantages, it is still necessary to pay attention to the correct operation and daily maintenance of the best automatic packaging machine during use, so as to improve work efficiency and reduce production costs.

The operation process of the automatic packaging machine:

1. Check before machine operation: Check that there are no sundries on the conveyor belt, work panel, and horizontal sealing knife seat, and that no one else is operating the machine.

2. Turn on the main switch of the power supply and the heater switch: then turn on the heating switch on the operation panel, and check the display temperature of each temperature controller. The heating temperature changes due to the change of paper film material, packaging speed and indoor environment.

3. Set the paper length and adjust the actual paper length: according to the length of the packaging film, set the paper length, run the kraft paper packaging machine without paper loaded, so that the actual paper length matches the set paper length.

4. Install the paper film to make it run smoothly, adjust the meshing center of the horizontal knife seat and the linear speed of the horizontal knife seat, and adjust the electric eye. Install the paper film and put it on in order, adjust the packaging speed to the lowest, start to adjust, adjust the height, left and right position and width of the paper bag packaging machine, adjust the meshing center of the horizontal knife seat to align with the height center of the packaged product, and adjust the horizontal sealing knife The linear speed of seat (referred to as "knife speed") is roughly the same as the linear speed of the paper film, that is, there is no paper accumulation or paper pulling, so that the paper film moves smoothly, and then adjust and align the electric eye.

5. Adjust the position of the product: put in the product that needs to be packaged, and adjust the position to make it in the correct position.

6. Carry out trial operation: After turning on the biodegradable packaging machine, speed up the packaging speed appropriately, and observe whether the adjustment results of the following steps are normal. If not, continue to adjust the previous steps. If it is normal, set the packaging speed to an appropriate value, and check whether the packaging appearance and sealing meet the requirements.

Requirements, (after the speed is increased, the temperature of the heater should be increased accordingly).

7. Enter normal production: After all the above adjustments are appropriate, it can enter normal production.

Cleaning of the automatic packaging machine

1.Maintenance and cleaning of the machine every day or every shift:

2. Clean the machine every time after finishing packing.

3. Before cleaning the machine, turn off the power.

4. When cleaning, do not spray water or steam directly on the machine

5. If product debris accumulates in the product transportation line, remove it with compressed air or other methods.

6. If film debris adheres to the sealing surface of the seal, brush it off with a wire brush coated with silicone oil.

7. Use a soft cloth to wipe off the dirt on the control panel, safety cover, and paint surface.

Inspection and maintenance of automatic packaging machine

1. Add grease to the end sealer (knife sealer) bearing.

2. Add grease to the gears and chains (wheels) in the transmission parts.

3. Check whether the chains and belts of the transmission parts are tensioned, and if they are loose, tighten them.

4. Check whether the set screws or nuts of each component are loose, and if they are loose, press them tightly.

5. Check whether the belt of the transmission part is worn. If the wear is serious, it needs to be replaced with a new one.

6. Check whether the rubber roller is worn, if it affects the paper feeding effect, it needs to be replaced with a new one.

7. Check all kinds of wearing parts and replace them in time.

8. Check whether the wiring on the electrical wiring board is firm, if it is loose, fasten it, check whether there is dust or dirt on the inverter, programmable logic controller, and circuit board, and blow it off with compressed air.

Lead Machery, a professional packaging machinery manufacturer, please contact us if necessary。