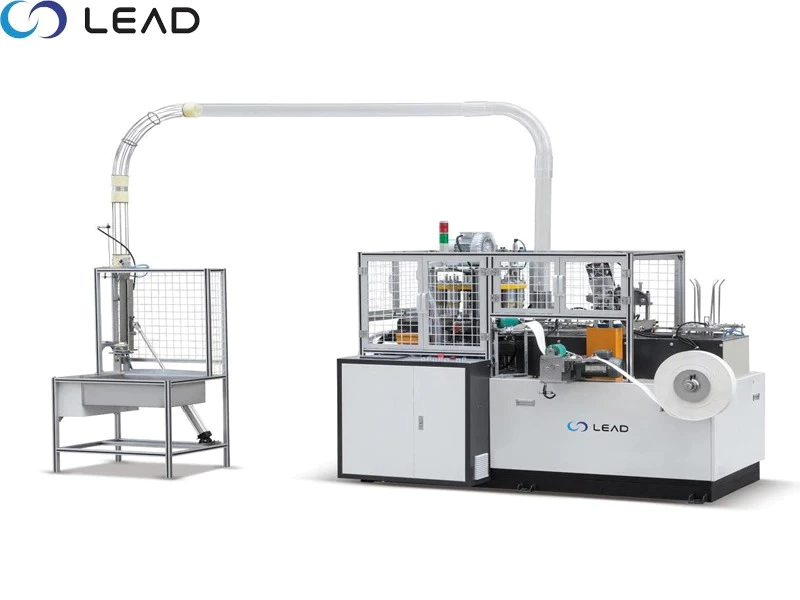

Four-side sealing tableware packaging machine

This automatic packaging line is automatic feeding products and wrap in a package. fork, spoon and knife napkin packaging machine can automatically complete the packaging of napkins, spoons, knives, forks, toothpicks, and salt and pepper packets. Widely used in restaurant tableware, aviation tableware, fast food tableware industry. It is a rotary automatic feeding system and can produce up to 150 packs per minute. Widely used in restaurant tableware, aviation tableware, fast food tableware industry.

Compact structure, stable performance and simple operation. Double frequency conversion control, the bag length can be set and cut immediately, no need to adjust the idling, one step, saving time and film. Adopt imported electrical appliances, touch-type man-machine interface, convenient and quick fault self-diagnosis function for parameter setting, and fault display at a glance. High-sensitivity photoelectric eye color tracking makes the sealing and cutting position more accurate.

Temperature independent PID control, suitable for coating of various materials. Positioning stop function, no sticking to the knife, no film. The rotating system is simple, the work is more reliable, and the maintenance is more convenient.

All controls are realized by software, which is convenient for function adjustment and technical upgrade

Technical Features

1. Panasonic PLC, Delta servo motor driving system are for automatic cutlery feeder and packing machine, which are more intelligent and more stable performance.

2. All the parts directly touching products are made of stainless steel 304 up to GMP and IFS.

3. The whole automatic packing machine is up to 120 bags/min in long term stable run.

4. The automatic spoon feeding system has more stable performance and longer service life, compare to other horizontal reciprocating type feeding system.

5. The cutlery loader can be customized according to product size and shape. When the cutlery has little difference, they can be load on the same magazine. When big difference, you just need to change magazine.

6. The cutlery packing machine has special sealing system. It can make a slim air hole, which can help to leak out the air in the bag. It can save space for later bulk package.

About purchasing:

1. Customer WhatsAPP or mobile phone to consult us

2. Understand from the quality of equipment and the scale of the company

3. Negotiate the relevant details, we can give you some product-related suggestions

4. Sign the contract

5. Pay the deposit

6. After paying the deposit - the production cycle is about 20 days, depending on the actual situation - pick up the goods

7. To pick up the goods, you can come to the driver to test the disposable packing machine to meet the requirements of the balance payment - delivery.

8. If the customer's specified requirements are not met, the deposit will be refunded in full, and the round-trip travel expenses will be reimbursed.

Pre-sale service:

Professional sales staff will explain the function and usage of the product in detail, and provide you with technical services such as workshop, layout, drawing design, personnel training and other technical services according to the different conditions of customers. Startup budget and advice.

On sale service:

Professionals and training provide you with technical consultation and training, fully understand the performance characteristics of the product, and conduct on-site training and practical exercises, so that you not only buy the equipment, but also master the technology. At the same time, the production process is further deepened.

After-sale service:

It is specially equipped with a group of professional and experienced technical masters to provide full tracking service, answer various difficult problems and needs of customers, and also visit customers regularly to help customers train technical personnel