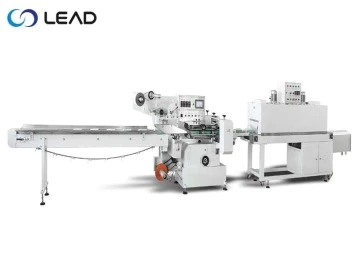

High-speed heat shrink packaging machine

Shrink wrapping process seals the items in a better and protective way and keeps out the dampness and the light induction during transit. This packaging process is excellent for the CDs, pharmaceutical products, and food items. A feature-packed shrink wrap machine supplied by the most reputed shrink wrapping machine factory & manufacturer can show the best performance.

Shrink wrapping is well known for being one of the low-cost wrapping or packaging solution, with the outlay for the shrink packing machinery. Polyvinyl shrink wrap films may seem to be the thinnest in the market but this doe not determine the strength of these. Having been tried as well as tested for so many years, this is the main reason that this is one of the best global packaging and wrapping solutions.t else we can do for you.Contact Lead shrink packing machine factory.

Heat shrinkable performance characteristics:

1. Single or arbitrary packaging.

2. The anti-cutting safety clutch device will not damage the package.

3. Increase the waste recycling device to make the packaging more beautiful, saving about 3%-10% of materials compared with the traditional packaging machine.

4. Color touch screen control system, easy to operate and beautiful in appearance; PLC control makes the system more stable, reliable, and has low failure rate; bag length, speed and temperature can be adjusted individually, easy and accurate to operate.

5. It can be equipped with a coding machine or an inkjet printer, without the need for manual labor.

6. With motor brake control, the equipment is responsive.

7. The heat shrinkable furnace has high-efficiency dual temperature zones, high-efficiency hot air circulation, and automatic temperature control to ensure shrinkage quality.

Technical Features of high speed shrink wrapping machine

1. Intelligent PLC controller system, 3 servo motor drive system. Packing length can be preset and cut precisely.

2. speed: 80-150 times/min, triple packaging capacity than traditional L-bar shrink wrapper and also higher speed than other similar machine.

3. Full wrapping: Compare to sleeve wrapping type, it can avoid staining due to expose to air.

4. POF wrapper: it’s more environmental friendly than PVC wrapper.

5. Packaging size is adjustable.

6. The automatic feeder can be customized to connect synchronic with shrink wrapping machine.

7. High effective shrink tunnel oven. Heat air cycle inner the tunnel is high efficient heating. Save the energy.

Shrink wrapping or bundle wrapping is the process of wrapping a group of items or a single product. The Best Shrink Wrap Machine, both automatic or semi-automatic, is used for this purpose. The application of heat shrinks and firmly conforms to the enclosed content's shape.

The three main wraps used in shrink packaging material for protecting and securing products for the retail and shipping environments are polyvinyl chloride (PVC), polyethylene (PE), and polyolefin (POF). Each has different capabilities and characteristics that make them suitable for specific applications.