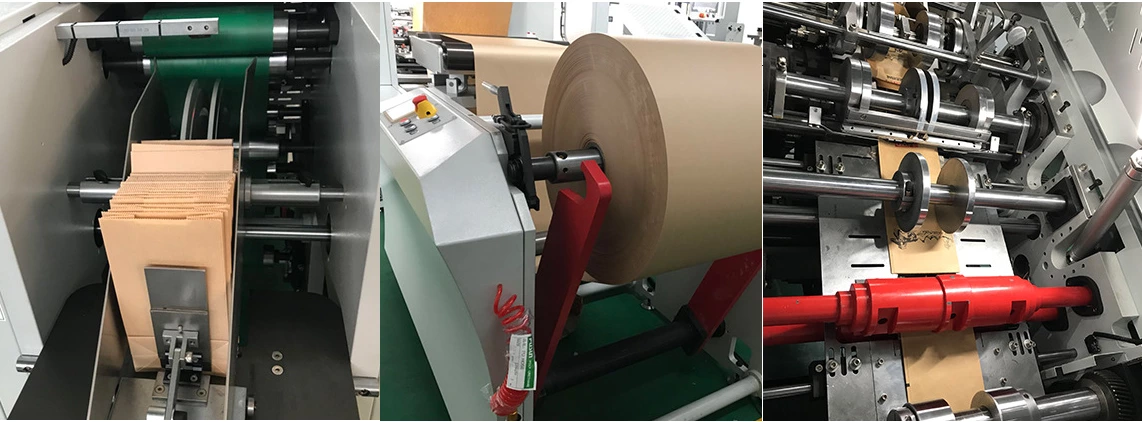

High-speed paper bag machine

This paper bag packing machine can produce paper bags of various sizes. It is also possible to design a kraft paper bag making machine with self-adhesive label function and a bag bottom with bifold function. We provide square bottom paper bag making machine, shopping paper bag making machine with handle function, and V-shaped bottom paper bag making machine. In addition to roll paper food paper bag making machine manufacturers, we also have many different types of paper bag making machines, using different types of paper materials or grades.The paper bag sealing machine is equipped with advanced electrical systems and mechanical devices from the base material delivery, tube forming, gluing, cutting bags, and conveying stacked bags.

Information details:

1. The bottom of the paper bag is sealed and glued, which is beautiful and durable, and better protects the bottom.

2. The sawtooth wave edge design can be matched with the label, which is convenient and fast.

3. Food packaging grade kraft paper, which can directly contact food, clean and hygienic.

4. The paper adopts automatic pneumatic device, and the manual switch on the paper is convenient, without manual operation.

5. The whole bag tube is used to adjust the structure, so that it can be adjusted from one side or both sides, so that the paper bag design is simple and stable, thereby reducing the adjustment time and unnecessary waste.

6. The length of the paper bag is controlled by a servo motor, and the perforation is uniformly rotated with a toothed knife to ensure that the incision is uniform and beautiful.

7. At the bottom of the glue structure, there is no glue tank type on the glue device, and the glue needs to be pulled upwards when the glue is stopped to solve the problems of too much glue leakage and too long glue stop time.

Main features of paper bag packaging machine:

1. Using the German original LENZE touch screen man-machine interface, the operation functions are clear at a glance and easy to control.

2. Using the German original LENZE motion controller (PC), through the high-speed bus Ether CAT, to ensure stable high-speed operation.

3. Using German original LENZE servo motor and German original SICK photoelectric eye correction to accurately track the size of the printing bag.

4. The loading and unloading of raw materials adopts hydraulic automatic lifting structure, and the unwinding adopts automatic constant tension control.

5. The raw material deviation correction adopts Italian SELECTRA to reduce the paper roll alignment adjustment time.