How about the disinfecting wipes produced by the disinfecting wipes machine?

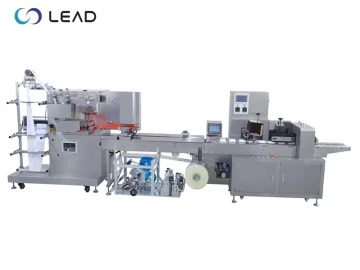

The disinfection wet wipes manufacturing machine adopts computer control, which can truly realize unmanned operation, high production efficiency and safe operation. Let us know about the disinfection wipes produced by the disinfection wipes machine.

Disinfecting wipes are divided into two types, one is used for cleaning and disinfection of small wounds such as scrapes, cuts and scratches and the surrounding skin, which can effectively kill bacteria up to 99.9% and prevent wound infection. Spunlace non-woven fabric as a substrate. The main components of the immersed liquid are benzalkonium chloramine, etc., cleaning and sterilization are completed at one time, 1 piece or 10 pieces are individually packaged, and the shelf life is two years.

The other has a broad-spectrum bactericidal effect, which can be used for skin cleaning, emollient, disinfection and sterilization, and can also be used for cleaning, disinfection and sterilization of daily necessities and sanitary ware, and can quickly and effectively kill Staphylococcus aureus and Escherichia coli. , Neisseria gonorrhoeae, Pseudomonas aeruginosa and other bacteria, spunlace non-woven fabric as the base material. The liquid to be immersed is pure water, natural bactericidal ingredients, aloe vera, lanolin, propylene glycol, etc. It does not contain alcohol and is mild in nature. It is packed in 10 or 20 bags and has a shelf life of two years.

How to adjust the knife holder of the disinfection wipes machine

The knife seat of the disinfection wet wipes machine is too high or too low, the packaging speed is too fast, and when the push rod and the cutter are not synchronized, the cutter will cut on the product. The maintenance method is to reduce the packaging speed, adjust the height of the end sealing parts, The center is in the middle of the product height. When adjusting, generally follow the instructions or contact the merchant.

Maintenance method of rodless cylinder for wet wipes packaging machine accessories

In the daily work, when the rodless cylinder on the china wet wipes packing machine has internal and external leakage problems, Jingwei pneumatic engineers have many years of rodless cylinder maintenance experience. I think the general reason is that the piston rod is installed eccentrically, the supply of lubricating oil in the cylinder is insufficient, the sealing ring and sealing ring of the rodless cylinder are worn or damaged, and it is more likely to be caused by impurities in the rodless cylinder.

Therefore, when the internal and external leakage occurs in the rodless cylinder, we should readjust the center of the piston rod at the first time, and first ensure the coaxiality of the piston rod and the cylinder; we must always check whether the lubricator works normally to ensure that there is no leakage. Rod cylinders are well lubricated. If the sealing ring and the sealing ring are worn or damaged, the sealing ring and the sealing ring must be replaced in time; if there are impurities in the rodless cylinder, the impurities should be removed in time to ensure the normal operation of the rodless cylinder

In the operation of the wet wipes packaging machine, some things must be paid special attention, which is very important for everyone. Many people are completely unaware of some specific things in the process of operating equipment, so it will directly affect the final result. So what problems should we pay attention to in the process of operation?

Learn how to do it right:

As a professional operator, we must seriously learn the correct operation method. Only when all of us can understand the specific operation method can we be guaranteed in the subsequent use process. Once many people are not familiar with the operation method learn. Then the whole application process will also be greatly affected, so everyone should understand the specific operation method in normal time.

Is there an exception:

Usually when using the wet wipes packaging machine, you also need to observe carefully to see if there is any abnormality in the equipment, and the work efficiency is everywhere. Under normal conditions, what are the specific methods of the equipment during use? Only by being able to correctly understand these specific situations and see if there are other abnormal problems in the equipment can help us to solve them better, pay close attention to these matters, and deal with problems in time.

Daily equipment inspection:

Before starting the device every day, you should check it, and you should also do some cleaning after use, and you can check the condition of the wet wipes making machine in time. If there are some problems, it needs to be solved in time. If there are no problems, it can be used again. Therefore, in the process of daily use, the inspection and maintenance work must be done well, so that the equipment will be used for a longer time, and other things can be effectively reduced.