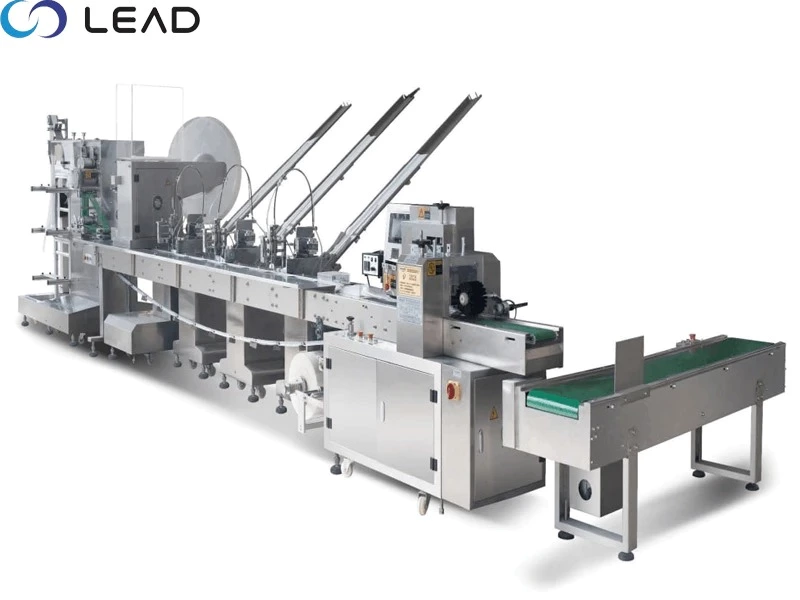

Introduction of paper straw packing machine

The paper straw packing machine for polypropylene beverage straws, packaging materials used for BOPP, PET, etc., can be heat sealed water pipe by the packing arrangement of type decorate, evenly spaced, connected the two hose among all passes through the continuous cutting, this can be in a certain number of rolls around, and can more easily single tear, the analysis of paper straw packing machine working principle should be: double plastic film in Heating under the state of sealing, cutting and composite forming. According to the working requirements, the straw packaging machine should have the functions of straw storage and delivery, packaging film delivery, horizontal sealing, and longitudinal sealing finished product output, etc., and the straw storage and delivery of the beverage tube packaging machine.

Preparation method of paper straw

Step 1: The bamboo pulp is pumped to the pulping pool after pulping. Add filler suspension and mix evenly, then pump to the slurry pond; Add nanocellulose, cationic starch, and alum, mix them evenly and pump them to the copying pond; After thickening and slag removal, sizing agent is added at the outlet of a section of good slurry, and wet strength agent, retention aid and stripping agent are continuously added online at the inlet of pressure screen into the slurry box. Step two, after the pulp on the machine, by the long net paper machine dehydration forming, press, using the former drying part of the dry, then by hydrophobically modified nano cellulose for spraying, into the drying part of the dry, the paper layer; Step three, the outer surface of the paper layer is coated with coating agent to form a coating layer; Step four, roll the custom straw packing machines into a tube to form a paper straw.

Benefits of paper straw

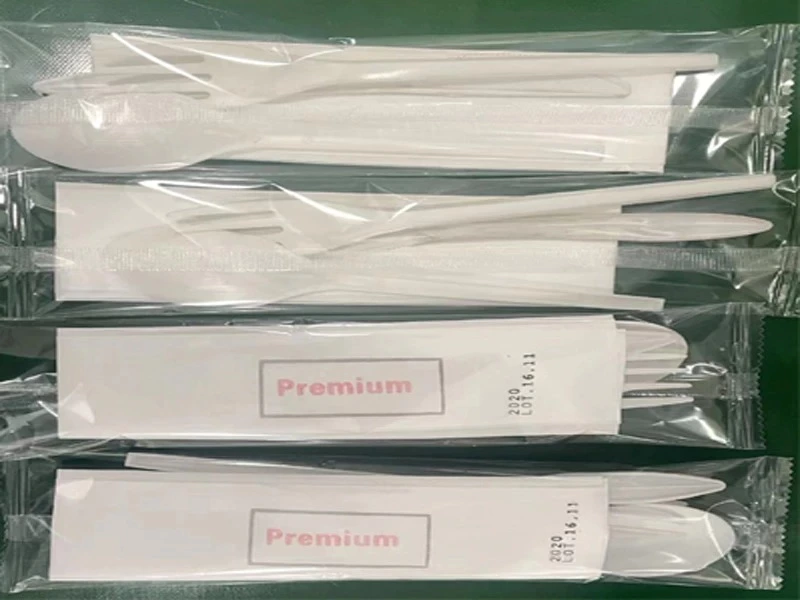

Most paper straw wrapping machines are degradable, can better replace the plastic straws used in the market, suitable for all kinds of people to use. Material can choose edible grade kraft paper, pure wood pulp paper, degradable paper, and so on. For the utility model with openings at both ends, a filter net can be added to the opening at the thicker end, and the filter net material can be made of nylon rubber. A large number of paper straw packaging machines use of a paper straw can better protect the environment, save costs, and in the society to promote more advantages, more can be widely recognized by everyone, simple and convenient to use.

Precautions during production

When running paper tube equipment, inspection should be carried out according to the requirements, especially for the tightened objects, to check whether they are loosened due to vibration, so that they can be tightened again. Before work, check the paper straw packing machines, machinery, and equipment. The air opening should run for some time, and only after it is determined that everything is running normally, To fund the operation of paper tube equipment, it is forbidden to run with common faults to prevent safety accidents. Manual adjustment is prohibited when paper straw mechanical machinery and equipment are running, and it is also forbidden to measure parts accurately or to moisten and remove debris. If it must be carried out, the mechanical machinery and equipment should be turned off first. To better achieve the aim of environmental protection and energy-saving, in the process of production, and also improve the test paper tube equipment and protection, if pressure, under-voltage protection, load moment shut off the power and restart the protection, to reduce energy consumption, it also has to speed up, slow down and to avoid the effect of dynamic rotation flutter, also can improve the reliability of paper straw packing machines .

If you want to know more about the automatic straw packing machine, you can visit our company's official website https://www.leadmach.com/. Ruian Lead Machinery & Technology Co., Ltd. focused on the production of high-quality paper straw packing machine products, and constantly improve the performance and reliability of the product, to provide users with an economic, practical, high-quality paper straw packing machine.