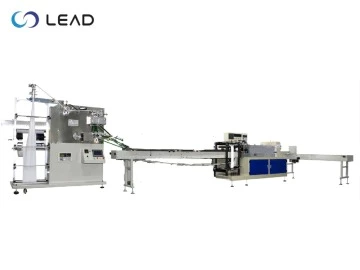

Introduction of wet wipes packaging machine

Composition of wet wipes packaging machine

With the rapid development of society and economy, people's lives are getting better and better. In the past, people invested abroad. Now, with the strengthening of life health and safety awareness, they began to invest in themselves, especially girls who love beautiful, often Overinvestment, buying clothes, shoes, cosmetics, wet wipes, facial masks, etc., but now online shopping malls are popular, many unsafe facial masks, wet wipes, cosmetics flow into the market, causing damage to consumers' skin.

The reciprocating knife frame device of the wet wipes making machine includes an inner knife frame and an outer knife frame. The main motor drives the main drive shaft through the reducer. The bearing is fixed on the inner side of the top of the inner tool holder. The main drive shaft and the passive shaft are driven by gears, synchronous wheels or chains. Slide blocks are installed at both ends of the upper beam with the upper tool seat and the lower beam with the lower tool seat. The blocks are respectively located in the slide rails on the inner side of the middle part of the inner tool holder, and the two ends of the upper tool holder are respectively fixed to the upper beam by means of buffer springs and buffer slide rails. Improve the stability of the mechanical transmission of the tool holder device, and at the same time improve the sealing quality of the tool holder.

Manufacturing process of wet wipes packaging machine

In the actual production process, several wet wipes can be put into the film packaging bag, and there is an extraction port on the front of the bag to extract the wet wipes. The cover is then re-adhered, and the wet wipes in the bag remain moist. The most distinctive feature is the innovative design of the punching die with extraction holes and the cover bonding device, which is a unique technology in China. In addition, an innovative design of the heat-sealing and cutting flow knife speed adjustable device is also used, which greatly improves the production efficiency and reduces the production cost. Each heating part of the wet wipes manufacturing machine is automatically controlled by a four-button temperature controller, and the sealing quality is high.

In a word, the wet wipes machine has novel structure, advanced technology and high production efficiency, which solves the defect of cross-contamination caused by manual packaging. And the external structure of the whole machine, the contact parts between the body and the product are all made of stainless steel and non-toxic materials, and all indicators meet the national requirements.

Product advantages of wet wipes packaging machine

Product advantages of wet wipes packaging machine: It is controlled by original servo motor, which is more intelligent, higher packaging precision, wider adjustable range, more precise control than other domestic and foreign similar frequency conversion motor or inverter controlled products. Lower scrap rate, better stability and lower noise. Due to the use of the world's leading fully open box structure, the transmission structure is clear at a glance, and maintenance is more convenient;

Features of wet wipes packaging machine:

1. Extraction hole punching die and cover page bonding device, this technology has domestic originality.

2. The speed of the heat-sealing and cutting hob can be adjusted, which can be used for multiple purposes, which greatly improves the production efficiency and reduces the production cost.

3. Adopt advanced PLC computer program control, the color mark is detected by the photoelectric detection sensor, photoelectric alignment, two-way compensation, so that the alignment is fast and accurate.

4. Each heating part adopts four sets of temperature controllers to automatically control the temperature, and the sealing quality is high.

5. The extraction port is bonded with self-adhesive, which has good sealing performance and is convenient to open and seal.