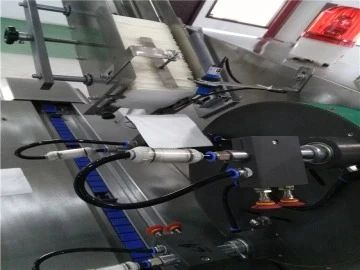

LD-LT550/400 Positive and negative pressure plastic thermoforming machine

LD-LT550/400 positive and negative pressure multi-station thermoforming machine is a new type of unit developed and produced by the company according to market and customer needs. Microcomputer touch display, human-machine interface, tunnel radiation multi-stage heating method to complete the baking of materials, convex and concave molds can be formed. Laser blade punching, heating, forming, punching. Cut. The stacking multi-station runs at the same time, that is, feeding, heating, forming, punching, cutting, stacking, counting, and conveying plastic sheets at one time, improving efficiency and reducing labor.

Features:

1. Adopt absolute control PLC and advanced automatic control system, precise operation and simple operation, suitable for PP, PS, OPS, PVC, APER, CPET and DW series materials.

2. The positive and negative pressure functions coexist, and the molding size of the product is accurate and stable.

3. Forming, cutting, stacking, and feeding are all controlled by servo, which is accurate and error-free.

4. Feeding, heating, forming, punching, stacking, counting, and conveying are completed synchronously, only one person is required to pack and put into the box, the product is safe and hygienic, and there is no secondary pollution.

5. The combination of positive and negative pressure, the thickness of the same material is better than the thickness of negative pressure blister products, the weight history is stable, and the thickness is uniform.

6. Apply silicone oil, vacuum several times, demould by vibration, traverse up and down, stretch up and down, the product effect is better.

7. Intelligent heating system, fast response, short time and high efficiency.

8. Using a new mold locking mechanism, the mold positioning is easy, the production is stable and efficient, and the mold can be fine-tuned during installation.

9. According to the specific planning of the customer's plant and equipment, three directions of equipment stacking and conveying are available for customers to choose.

10. Our standard equipment includes five stations for forming, punching side holes, punching bottom holes, cutting and stacking. Customers can choose the functions of the equipment according to their own product needs.

Applicable country:

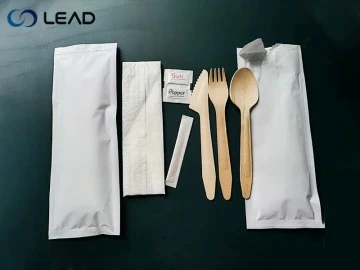

Professionally used for thermoforming of various plastic sheets such as PP, PS, HIPS, PVC, PET, OPS. EPS, PLA. ABS, etc. It can be widely used in the production of disposable plastic cup lids, supermarket trays, tofu boxes, ice cream cups. All kinds of canned food boxes, preserved fruit boxes, pickle boxes, candy boxes, chocolate boxes, pastry boxes, all kinds of vegetables, fruit packaging boxes, egg trays, seedling trays, various aquatic products, quick-frozen fresh-keeping boxes, medicine boxes, medical equipment boxes. Toy boxes, hardware boxes, stationery, clothing boxes and all kinds of daily necessities packaging boxes and various packaging products for the industry.

Main Technical Parameters: