Maintenance of paper cup flexo printing machine

Pay attention to the oil quantity and oil temperature when the china flexo printing machine for paper cup is turned on. Do not start the machine at high speed without lubrication as this will damage the machine. When it is necessary to perform circumferential plate matching, start the circumferential plate adjustment motor to generate positive and negative rotation speeds for the planetary wheel carrier, so as to realize the superposition or subtraction of the printing roller rotation speed to the synchronous rotation speed, so as to complete the required direction of the plate registration in the circumferential direction.

Flexographic printing machine have corresponding requirements for the synchronization of printing unit power, the balance of ink supply, and the balance of plate rollers during the printing process. The printing power of the cup printing machine is delivered by the main motor to the reducer of each unit, and each color group runs synchronously. To make the overprint stable, the gearbox needs to be well maintained.

The squeegee is used to ensure an even supply of ink to the printing plate. If you don't need a scraper, use a rubber roller to transfer the ink and press it with an anilox roller, the ink will turn fast and slow. The ink volume of the anilox roller is very different. When the anilox roller rotates fast, the ink volume is large, and when the anilox roller rotates slowly, the ink volume is small. For this purpose, a doctor blade is provided on the china flexographic printing machine.

Anilox roll is an accurate ink transfer roll. The amount of ink transfer is determined by the number of lines per inch. The more lines, the more pits, and the less ink. Fewer lines, fewer pits, and more ink. The number of screen lines of the cylinder in printing is reasonable, which is determined by the color requirements of printing. Therefore, in the process of maintenance of the printing press, these requirements must be done well, so as to ensure its good performance.

What are the common methods for cleaning anilox rolls?

1. The anilox roller is immersed in an ultrasonic cleaning system tank filled with chemical cleaning fluid. The frequency conversion device in the tank emits high-frequency sound waves, which make the solution vibrate to generate bubbles. The dry ink, resin and coated cloth in the ink hole flow out from one of the ink holes and flow together with the cleaning liquid under the combined action of the solution vibration and the inward explosive force generated by the directional explosion surface of the bubble. The cleaning time depends on the size of the drum and the clogging of the base ink, generally 0.5-24 hours. During this time, the drum runs for a long time under high-frequency vibration, which will cause corresponding damage to the ceramic layer, the ink layer of the drum, and the ink hole. In addition, the method requires a large area, high investment cost and complicated process. Although there is a corresponding cleaning effect, the integrity of this method remains to be tested.

2. Spray chemical solvent on the surface of the anilox roller, select a suitable fine brush according to the material of the anilox roller of the paper cup flexo printing machine (stainless steel brush for ceramic anilox roller, copper wire brush for metal anilox roller), and brush repeatedly. This method is suitable for the cleaning of thick line anilox rollers. The advantage is that the cost is low, the cleaning is convenient, and there is no pollution to the environment; Dirt and ink at the bottom of the ink holes are difficult to clean. Therefore, the volume of the ink hole cannot be recovered.

3. Use sodium bicarbonate, sodium bicarbonate and sodium bicarbonate as cleaning powder, spray into the drum under low pressure, thoroughly clean the dry ink, resin and cloth left in the ink hole, but pay attention not to spray too high pressure, otherwise it may cause The ceramic layer is separated from the drum body, and the general pressure is not more than 0.1MPa. Since sodium bicarbonate and sodium bicarbonate are softening cleaning media, they are easily soluble and meet my country's environmental protection requirements. Practice has proved that this method has a good cleaning effect, can restore the ink hole volume, and can be directly cleaned on site, including ink buckets, grease, ink, etc. Therefore, when cleaning the anilox roller of the flexographic printing machine for paper cup, attention should be paid to the maintenance in use.

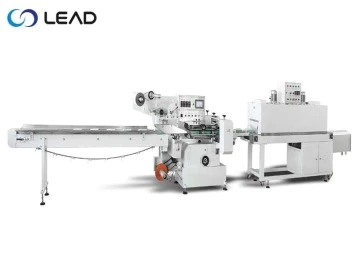

If you have any questions or want to buy, you can consult our online customer service in detail or directly call us and we will serve you wholeheartedly.Ruian Lead Machinery & Technology Co., Ltd. is a professional wet wipes machine manufacturers.We were dedicated in soft packaging machinery designing&manufacture, and intelligent packaging solution providing. Our main series products are based on flow packing machine. And extend to various automatic feeding solution. E.g. automatic disposable tableware kit packing machine, automatic bath boom feeding & shrink packing machine, automatic battery feeding & packing machine.