Manufacture Of Disposable Spoon Packaging Machine

Cutlery Packaging Machine is an automatic operation where the bag forming filling, sealing and filling of cutlery items is fully automatic. Easy to handle and operate equipped with all contact parts of stainless steel. The wholesale automatic packing machine can be used for packing disposal cutlery products.

Manufacture Of Disposable Spoon Packaging Machine

1) The utility model has the advantages of simple and reliable structure, convenient manufacture and easy debugging.

2) Minimize the resistance of the film through the former, so that the film will not produce longitudinal or transverse tensile deformation and wrinkles.

3) Ensure that the film fits naturally, has no tension and space, passes through the former, rolls naturally and forms correctly.

4) The commonly used shapers mainly include the following: 3.1.1 special bag shapers. Special bag shapers mainly include Lapel shapers, U-shaped shapers, elephant trunk shapers, V-shaped shapers and triangle shapers. Different shapers have their own advantages and disadvantages in structure and performance, and their application fields are also different.

What is the working principle of the disposable spoon packaging machine? Why can the disposable spoon packaging machine practice automatic packaging of spoons? The operating system of the disposable spoon packing machine.

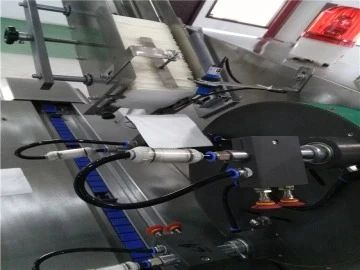

Under normal circumstances, under the traction of the longitudinal sealing roller, the roll film enters the bag forming machine through the guide roller to form a kind of paper tube. The longitudinal sealing roller seals the two edges of the paper tube while pulling. Subsequently, the transverse sealing and cutting are performed by closing the transverse sealing roller. Likewise, each horizontal sealing action can simultaneously complete the sealing of the lower opening of the upper bag and the upper opening of the lower bag, and cut and separate. The filling of the material is completed before the paper tube is pulled down by the vertical seal to the horizontal seal.

Disposable packing machine is a widely used model, and it has become the most used design because of its rationality and scientific packaging principle. According to this packaging principle, a variety of bag types can be designed. For example, a pair of longitudinal sealing rollers are added, so that the two pairs of longitudinal sealing rollers are symmetrically arranged on both edges of the paper tube, and two longitudinal sealing seams are formed when the longitudinal sealing is performed at the same time. This bag-making method is mainly based on the simplification of the former, which makes the processing of the former simple and saves costs. A pair of symmetrical formers is used, and two paper feed rolls are used, and paper is fed on both sides at the same time. The packaging is symmetrical and beautiful, which plays a role of symmetrical beauty. To sum up, the vertical continuous bag making 4 side seal packaging machine is adopted, which combines the longitudinal sealing and traction into two pairs of longitudinal sealing rollers, which saves space, improves efficiency and simplifies the structure. Taking into account the characteristics of convenience and low cost, the vertical continuous bag-making four-side sealing and packaging machine was selected this time.