Paper cup forming machine丨LEAD

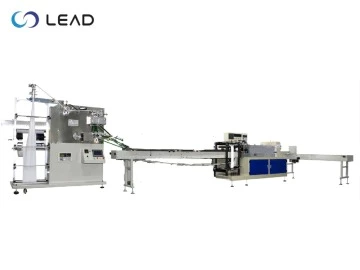

The automatic high-speed paper cup forming machine adopts an open intermittent indexing mechanism, gear transmission, and longitudinal axis structure, so as to reasonably distribute various functional assemblies.

The cup-making process is controlled by PLC, using photoelectric eye to monitor the whole fault, servo feeding, thereby improving the performance of the equipment, achieving fast and stable operation, realizing the automatic shutdown of the fault, reducing the labor intensity of the workers, and improving the safety and stability of the equipment. By simplifying the cup making process, paper feeding, gluing, bottom feeding, cup loading, heating, roll bottom, knurling, roll opening, cup unloading, detection, automatic counting and receiving cups are integrated, up to 90 pcs/min

FEATURES

1. Three times of paper feeding and multiple adjustments to avoid unevenness on both sides of the paper cup.

2. The ultrasonic welding system is adopted to increase the heat dissipation and speed up the cooling, so that the paper cup machine can maintain a proper temperature during operation.

3. The encoder and the light eye control the machine at the same time, one fan piece is matched with one cup bottom to avoid waste, fault alarm, and automatic shutdown.

4. The inside of the machine is connected by a sheave, and all parts are tighter, it is not easy to loosen during the operation of the machine, and the work is more accurate.

5. The equipment adopts the direct bottom-feeding method, which can be done in one step to avoid turning over the bottom.

6. Guided by the conveyor belt, the waste paper is discharged to avoid the waste paper being transferred into the wholesale paper cup machines when the machine is running, which is not easy to clean and affects the normal operation of the machine.

7. Using PLC control to improve intelligence, the stroke is more precise and accurate, and labor is reduced.

Lead Machinery has many years of experience in packaging machinery, and is very professional.

After-sales service: The price of our products is not the product itself, but our service.

Questions about the machine: Except for the wearing parts, it is the manufacturer's quality problem that the manufacturer replaces for free (and we pay the freight), and we provide spare parts caused by improper operation of the customer (the customer pays us for the spare part).

Small problem: telephone to guide maintenance, we will send you the bad parts.

Big problem: door-to-door service, as long as there is a problem with our company's products, we will provide maintenance, and we will provide free services (maintenance, sending parts) for quality problems of our products, and the customer will be responsible for the customer's improper operation. The production cost of parts, if there is a big problem, you can travel for service

pre-sale service:

Professional sales staff will explain the function and usage of the product in detail for you, and provide you with technical services such as workshop, layout, drawing design, personnel training and other technical services according to the different conditions of customers. Startup budget and advice.

On sale service:

Professionals and training centers provide you with comprehensive technical consultation and training, fully understand the performance characteristics of products, and conduct on-site training and practical exercises, so that you not only buy equipment, but also master technology.

After-sale service:

Specially equipped with a group of professional and experienced technical masters to provide full tracking service to answer various difficult problems and needs of customers.

1. Telephone (priority) or online consultation - we will recommend suitable paper plate making machines to you according to your company's needs! If you have any questions, please contact: Whatsapp+8618066476286 Cheng Manager

2. Confirmation of product details - material samples can be provided, and the full actual thickness of the material can be promised

3. Confirmation of cooperation method --- Both parties confirm the cooperation details such as product quantity, price, delivery date, payment method, etc.

4. Signing a contract---a formal contract with the company's official seal and legally binding