Single row fifty paper cup shrink wrap丨Heat shrink丨LEAD

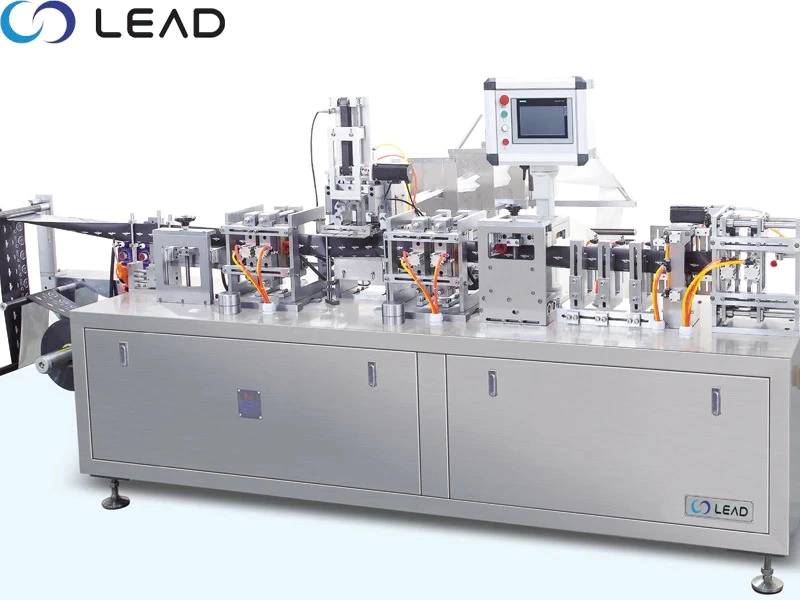

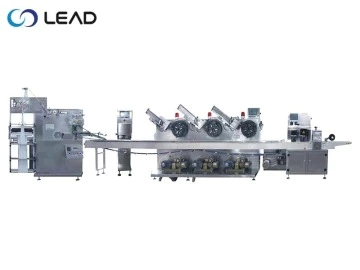

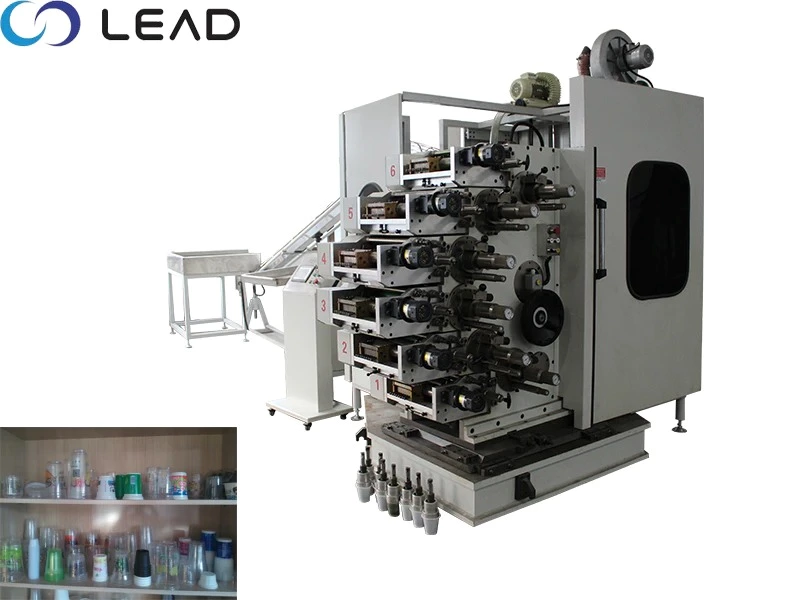

Cup heat shrink packaging machine is suitable for group packaging of food, medicine, beverages, bowl noodles, milk tea, mosquito coils, wallpaper, exercise books, filters, electrical switches, plastic wrap, garbage bags, various stationery, industrial parts and daily necessities Cosmetics body packaging, etc. Monolithic or random packaging. The anti-cut safety clutch device will not damage the package. Add a waste recycling device to make the packaging more beautiful, saving about 3%-10% of materials compared to traditional packaging machines.

Color touch screen control system, easy to operate and beautiful in appearance; PLC control makes the system more stable, reliable, and has low failure rate; bag length, speed and temperature can be adjusted individually, easy and accurate to operate. It can be equipped with a coder or an inkjet printer without the need for manual labor. With motor brake control, the equipment is responsive. The heat shrinkable furnace has high-efficiency dual temperature zones, high-efficiency hot air circulation, and automatic temperature control to ensure shrinkage quality.

Feature

1. Automatic counting, feeding and packing by single row or 2 rows.

2. Option with one or two rows packing, only one row counting,

3. Cup counting and packaging is the two independent parts, can be operated alone.

4. Distance between with two cups only needs 2 mm

5. High efficient shrink tunnel.

Main electrical pneumatic parts brand

1. PLC is Siemens in Germany

2. Touch screen is MCGS in Beijing

3. Inverter is Schneider in France

4. Servo motor is Mitsubish in Japan

5. Proximate switch is Omron in Japan

6. Photo-electrical sensor is Omron in Japan

7. Main motor is XILING in Shanghai

8. Breaker is CHINT in China.

9. Switching power supply is Mingwei in Taiwan

10. Temperature controller is Yatai in Shanghai

11. Electromagnetic valve is MINDMAN in Taiwan

12. Cylinder is Airtac in Taiwan

Tech Para

|

Item |

LD-CP600 Automatic cups counting&packing machine |

|

Packing Material |

OPP/CPP |

|

Wrapping film roll |

600mm / 18-25microns |

|

Bag type |

Pillow bag, gusseted bag, punching bag, |

|

Bag-making Size |

(L)60-800mm (W)60-200mm(H) 60-95mm |

|

Cups No. In stack |

10-50pcs in a stack |

|

Packing Capacity |

10-30 packs/min. |

|

Air consumption |

0.8Mpa 0.5m3/min |

|

Power |

AC 220/380V 50/60HZ, 15.8Kw |

|

Overall Dimension |

(L)8550 x (W)1200 x (H)1100mm |

|

Machine weight |

1800Kgs |