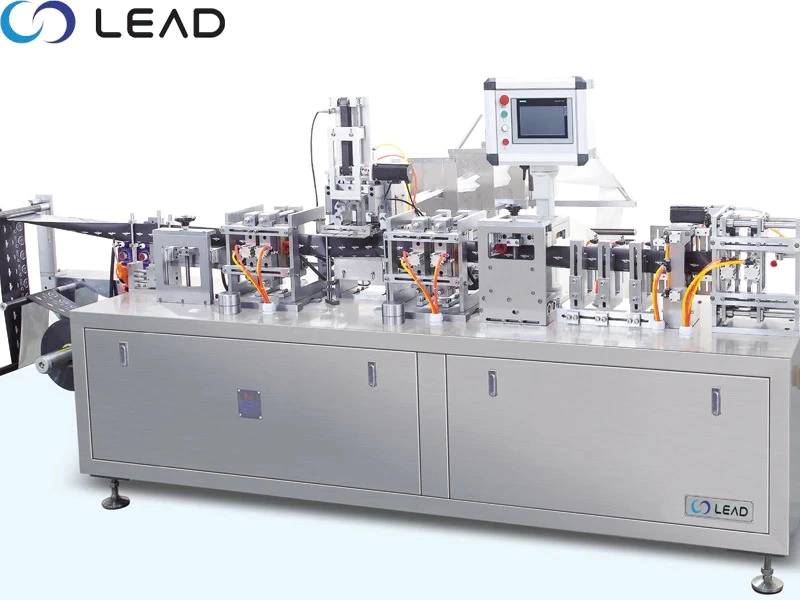

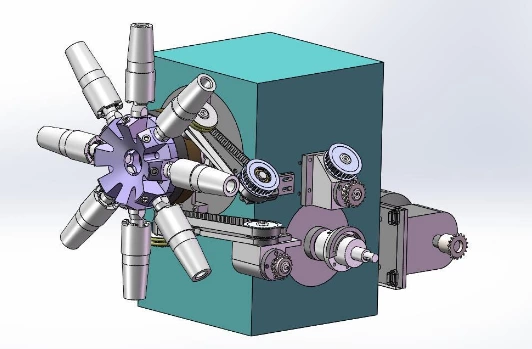

Six color cup printing machine

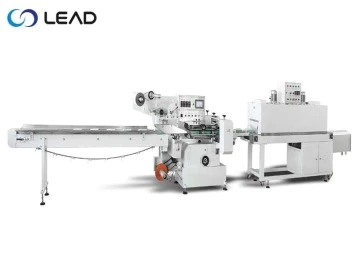

The six-color curved surface offset press adopts a reasonable structure and high-quality accessories to ensure the machine is durable, practical, high-quality printing, high-efficiency, and easy to operate. This machine is letterpress printing, mainly suitable for surface printing of cups and bowls.This machine adopts international advanced technology, high-precision manufacturing technology, reasonable structure and high-quality accessories to ensure that the machine has the characteristics of durability, practicability, high printing quality, high production efficiency, automatic packaging and easy operation. This machine is letterpress printing. , Mainly suitable for surface printing and automatic packaging of cups and bowls.

Features:

1. Equipped with a lifting cup conveying buffer area, which is convenient for the compensation of the cup, and solves the problem that the traditional conveyor belt is prone to failure due to the large arc of the conveyor belt.

2. Equipped with a four-screw cup feeder, which adopts a self-locking one-axis linkage four-screw to adjust the position of the screw.

3. Equipped with automatic detection of no cups, double cups, cup sleeves not in place, and pinhole cups.

4. Equipped with 2 sets of pre-press corona surface treatment systems (4 surface treatment devices) with pinhole detection. The power of the corona is increased or decreased with the speed of the machine. The surface treatment will not damage the cup at high to low speed, and there is enough power surface treatment at high speed.

5. Equipped with a synchronous cup top device to reduce the pattern displacement of the cup during printing.

6. Equipped with defective product processing system

7. Equipped with a four-helix 45-degree cup stacker, which adopts a self-locking one-axis linkage four-helix to adjust the position of the screw; the helical 45-degree cup stacker can not only stack cups with a diameter smaller than the height, but also stack large bowls with a diameter larger than the height.

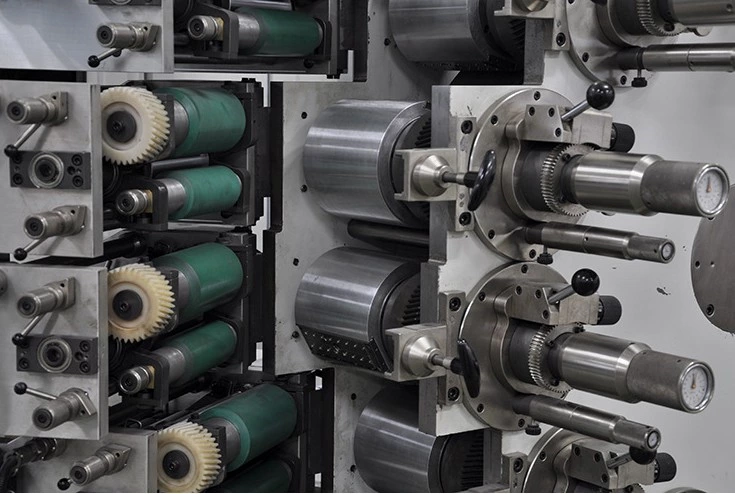

8. The eight printing dies are driven by one rubber wheel, which keeps the printing die in contact with the rubber wheel. Compared with the rubber wheel drive corresponding to the printing die independently, it reduces hundreds of impacts per minute, so one rubber wheel drives 8 The life of a mold will be longer.

9. The PLC automatically limits the speed of the machine according to the input weight of the printing mold to ensure that the machine is not damaged.

10. The printing mold adopts the design of quick replacement.

11. The ink unit can be opened at 80 degrees, and the double rubber rollers contact the printing plate at the same time to transmit the ink, which improves the printing effect and avoids poor printing due to surface damage of the rubber roller. cleaning.

12. Fully automatic detection of fault information of automatic system, UV system, corona system, and all-machine sensors.

13. Equipped with automatic positioning punch for printing plate.

14. Equipped with automatic counting, accurate counting.

The main features are:

1. Horizontal automatic feeding

2. Surface corona treatment, can also be configured to eliminate static electricity settings;

3. One handle for cup adjustment, easy to adjust;

4. The printing cylinder is automatically separated when there are no cups and double cups

5. The roller gear automatically adjusts the gap, and the printed part has no shadow

6. The printing plate has a special punching machine, which is accurate, fast and easy to operate.

7. The mold core and die head are easy and fast to replace

8. Corona hole inspection function

9. Sampling function of printed parts in work

10. Automatic counting function

11. Automatic drive transfer rubber mode