What is cutlery packing machine?

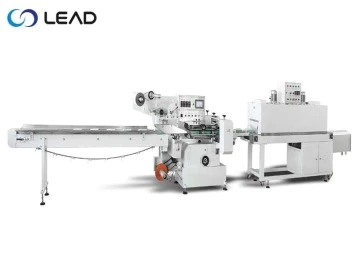

The cutlery packing machine is mainly composed of a conveyor, a packaging host, an output machine, a shrinking machine, and four major parts. The delivery method is:

(1) Place the material on the conveyor.

(2) The material is sent to the bag maker by the conveyor, and the material is wrapped while the bag is being made.

(3) The wrapped material is first sealed by the vertical sealing knife, and the cut waste is rolled up and recycled by the waste recycling device, and then transported to the horizontal sealing knife by the upper and lower clamps for sealing and cutting at both ends.

(4) The sealed and cut materials are sent to the shrinking machine through the output machine for shrinking, thus completing a complete shrink packaging.

Features of cutlery packaging machine :

The tableware package packing line china has the characteristics of simple operation, high degree of automation, fast efficiency, low packaging cost, labor saving, reduction of damage and secondary pollution, etc. It is widely used in the heat shrink packaging of tableware in various disinfection companies. It is a very mature product. model.

Save labor, save electricity, improve packaging efficiency, and reduce packaging labor intensity;

Bag making, filling, sealing and cutting are completed at one time;

Adopt photoelectric tracking technology, digital input, accurate sealing and cutting position;

Touch mode man-machine interface control, parameter setting is convenient and quick;

High-speed packaging, stable performance, beautiful shape, simple operation and convenient maintenance;

Optional coding device, free to choose coding;

Avoid secondary pollution of tableware packaging due to direct contact with manual packaging;

Reduce the cost of packaging materials.

In view of the characteristics of sterilized tableware packaging, which are characterized by many people, easy damage, large quantity, low profit, high temperature and humidity on the work site, and high distribution efficiency and strict hygiene requirements, we have made the following improvements to this machine;

(1) Imported moisture-proof electrical components are used, and PLC programmable logic and frequency conversion technology are used for microcomputer control to ensure simple and reliable operation, high efficiency, up to 10-100 packs per minute, and beautiful packaging.

(2) Equipped with an anti-cutting safety clutch device, which can effectively prevent the cutlery from being cut and greatly reduce the breakage rate of the cutlery.

(3) The lengthened chain plate conveying is adopted, which will not move and roll during feeding, and will not affect the packaging speed due to the packaging of wine glasses, tea cups, spoons, etc. falling out of the plate.

(4) The improved paper bag forming device not only makes the packaging effect more perfect, but also saves the cost and keeps the work site clean.

(5) Due to the humidity in the working environment, the shrinking machine adopts a stainless steel heating tube with a thermal cycle and a dual temperature zone to control the furnace temperature, so that the expansion and contraction process is more perfect and the shrinkage effect is better. So that the heat shrink machine will never rust, more durable, and more power-saving.

Problems with cutlery wrapping machine

1. The packaging bag cannot be sealed;

2. The bag is sealed under the pressure of the sealing knife, but it is opened by tearing or squeezing it with a little force;

3. The sealing is half sealed and half separated. The quality of such sealing is still unqualified. This situation occurs when the composite lining is OPP and blow-molded PE. All three cases are caused by poor sealing.

Solve the problem of cutlery machine

Insufficient heat sealing temperature: just increase the heat sealing temperature appropriately to solve the problem.

The heat sealing speed is too fast: the speed of the sealing machine will also affect the sealing effect. If the sealing speed is too fast, the sealing part will be transported by the traction roller to the cold pressing place for cooling before it can be heated, which will also cause the sealing to be weak.