What is paper cup machine?

Requirements for the selection of cup materials for paper cup machine

The paper cup machine is a disposable cup making machine specially used to produce paper cup products. It can produce single and double-sided PE coated paper cups, and control the size and weight of the paper cups.

Paper cups are containers used to hold liquids, and the liquids contained are usually edible. Therefore, we can learn from here that the paper cups produced by the automatic paper cup machine must meet food safety regulations. Therefore, its paper material is best to choose base paper instead of secondary processed paper material;

Secondly, it is necessary to choose paper materials that do not contain or meet the corresponding industry standards of fluorescent substances, and do not choose paper materials with excessive fluorescent substances because of low prices. This excessive substance has great harm to the human body.

Finally, the paper cups produced by the paper cup making machine contain liquid. Therefore, the paper material must have certain water resistance and pressure resistance, so that the paper cup machine is not easy to break and leak water when the cup is formed.

Usually, during the production process of paper cups, they will be treated with PE lamination by paper cup machine. This process adds a layer of inner film to the inner layer of the paper cups, which can withstand high temperature and water.

If the paper cup manufacturing machine uses wax treatment for the paper cups, it is necessary to make a special note on the outer packaging, indicating that this paper cup is suitable for holding liquids with low temperature, but not suitable for high temperature liquids.

What are the production equipment for disposable paper cups?

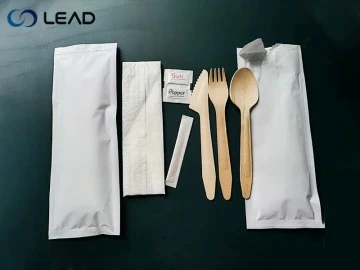

Disposable paper cups can be divided into three types according to their uses, cold drink cups, hot drink cups and ice cream cups; and according to the coating used on paper cups, they can also be divided into three types, wax-coated cups, polyethylene-coated cups and straight-wall double-layered cups.

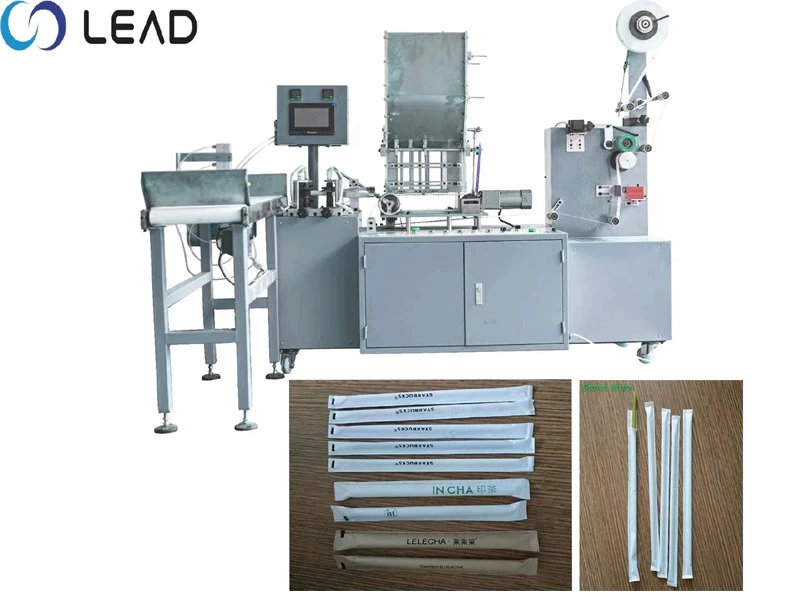

1. The high-speed paper cup machine is a high-performance automatic machine with double turntables and double dividers. Cups and other functions, the production of cups with single-sided and double-sided film-coated cold drink cups, milk tea cups and other cups.

2. The automatic medium-speed paper cup machine is a multi-station high speed paper cup machine with automatic paper feeding, heat sealing into a tube, cup opening lubrication, punching and pressing the bottom of the cup, heating the bottom of the cup, rolling, fitting Continuous processes such as hemming, finished product blowing, etc., can be adapted to produce single and double-sided cold and hot drink paper cups, ice cream cups, etc.

3. The automatic paper cup forming machine is a small machine specially developed for cups under 12 ounces. It is a multi-station automatic paper cup making machine, which through automatic paper feeding, middle sealing and forming into a tube, cup bottom lubrication, bottom paper punching, heating, bottom knurling, upper edge curling, piping, unloading, stacking finished products and other continuous processes , The production of paper beverage cups, ice cream cups or other food cone-shaped containers.

Development of paper cup machine industry

If the paper cup machine remains unchanged, it is easy to be eliminated, so if you want to remain popular, then the paper cup machine must carry out new product development.

1. The technical content of paper cup machines is increasing day by day: some existing low cost paper cup making machine products in my country are not high in technical content, while foreign countries have applied many advanced technologies to paper cup machines.

2. Specialization in the production of paper cup machine parts: The international packaging industry attaches great importance to improving the general capabilities of the paper cup machine and the entire system. Therefore, the specialization of paper cup machine parts production is an inevitable trend of development.

Many parts are no longer produced by paper cup machine factories, but by some general standard parts factories, and some special parts are produced by highly specialized manufacturers. This is because many control components or structural components of the paper cup machine are the same as general equipment and can be borrowed.

3. Towards multi-function and single high-speed polarization. The ultimate goal of the disposable cup machine is to increase productivity and diversify products. This makes the product specifications of the paper cup machine develop in a polarized direction, that is, multi-function and single high-speed.