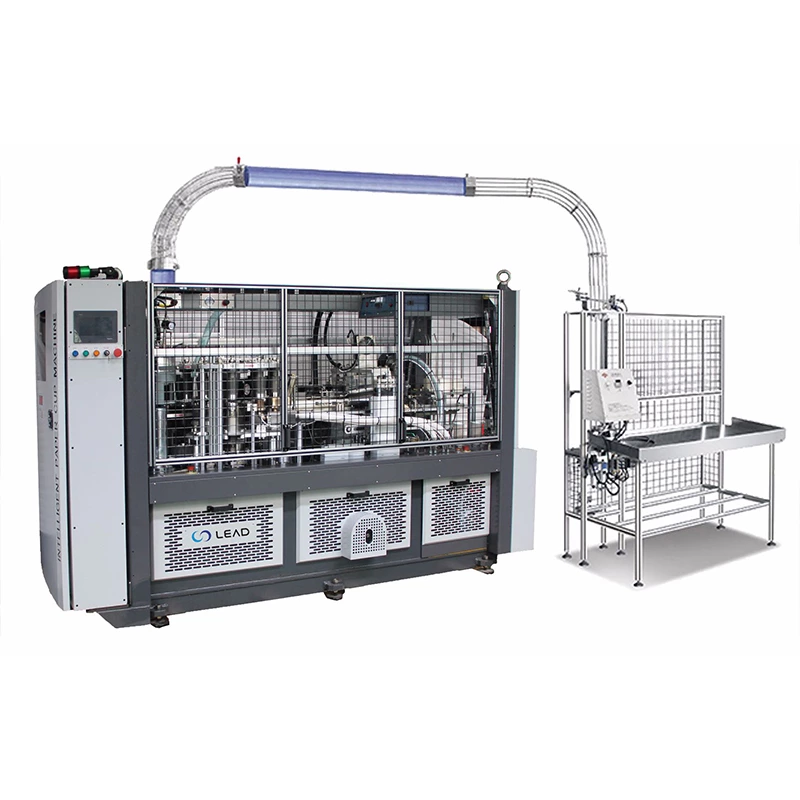

LD-BM1250C High Speed Intelligent Paper Bowl Machine

- Model:

- LD-BM1250C

- MOQ:

- 1 set

- Payment:

- L/C,T/T

- Place of Origin:

- China

- Brand:

- LEAD

- Delivery Time:

- 7-20 days

The LD-BM1250C model high-speed intelligent paper cup machine adopts a desktop layout, which isolates the forming mold from the transmission part. The transmission parts are arranged in the frame box under the table, and it is automatically sprayed and lubricated. It adopts the longitudinal axis transmission structure, the open cylindrical indexing mechanism and the gear transmission. Various molding dies are set on the table, which is convenient for cleaning and maintenance. Electricity adopts PLC control, whole process photoelectric tracking monitoring, servo feeding.

Technical Features

1. Multi-model frame. Use simple window prompts for guidance to select the model to set up.

2. Flexible parameter setting. You can backup, restore or restore parameters to factory. You can also manually modify the parameters in detail.

3. Flexible encoder origin setting and direction automatic setting and fault self-checking. The hardware installation of the encoder does not need to consider the location, just set the software.

4. Automatically configure the parking space, and quickly drop in less than one lap. Once configured, the machine will automatically calculate the inertial distance of the machine, at least one step faster than the decelerated position.

5. The key station sensor signals of the system are automatically calculated and identified. The molding failure can be encountered by simply operating the start button, and the system automatically tracks the signal according to the sensor, so that the mold quickly stops in the middle of the two heaters.

6. Stop the automatic cup removal. After the machine stops abnormally, the system will automatically remove the heater and bracket position because the heater is burned out and the adhesive is not strong.

7. Intelligent temperature control of heating system. The temperature is controlled by PLC PID, the user only needs to select the paper manufacturer, weight, single/double PE, the system will automatically set the corresponding target temperature, and the speed of the machine will change when the target temperature is automatically adjusted. Users can also customize the target temperature control curve.

8. Visual system defect detection. Automatically identify paper cup shape, interior, bottom defects, and automatically remove them. Unique algorithm, accurate and stable identification of light gray stains. One key to quickly set parameters, you can also modify each parameter in detail. The system supports internal network monitoring output reports.

Technical Parameter

| Model | LD-BM1250C |

| Weight | 3300kg |

| Encasement dimension | 2920x1600x2350mm |

| Cup counting holder packing specifications | 1230x720x1900mm |

| Rated power | 380V、35KW |

| Air supply requirement(by customer) | 0.6-0.8Mpa、0.5cube/min |

| Capacity | (L)60-300mm (W)30-100mm(H) 10-40mm |

| Paper materials | PE/PE/PLA |

| Paper grams | 200-330g/m2 |

| paper cups specifications |

Cup diameter 100-145mm Cup height 50-110mm Cup bottom diameter 80-115mm Bottom depth 5-10mm |

|

|

|

|