Multi-color plasticine packaging machine

- Model:

- LD-MC-50/350

- MOQ:

- 1 set

- Payment:

- L/C,T/T

- Place of Origin:

- China

- Brand:

- LEAD

- Delivery Time:

- 7-20 days

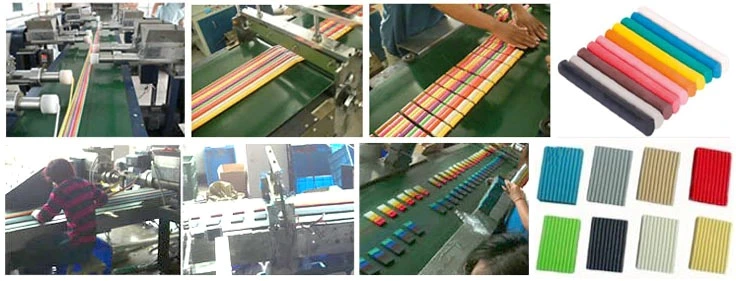

LD-MC Multi-color plasticine packaging machine

This machine are used to extrude many different color plasticine bar and cut, then pack in a BOPP wrap bag.

Technical Features

1.The whole line contains 6 extruding equipment, cutting equipment, conveyor and packing machine.

a. 6 different color clay bar can be made at the same time.

b. When making 5 color bars, 1 extruding equipment can be close and don’t work.

c. You can make different shape and dimension bar just by changing different extruding mould.

d. Double screw extrusion system is special design for paraffin and vaseline based clay, which can make sure smooth surface and continous extrusion.

2. PLC control system and touch screen display,easy operation panel.

Dual frequency converter control,bag length can be set and cut precisely, saving time and film.

3. Cutting equipment is controlled by servo motor. It has more durable service life comparing to pneumatic system.

4. The fault is automatic displayed on the screen.

5. Import brand photoelectric sensor track color mark high sensitive. No need to set the length of bag,intelligent cutting length.

6. PID digital temperature controller for perfect wrapping.

Technical Parameter

| Part A + Part B | Multi-color plasticine extrusion machine | Flow packing machine |

| Hopper size | 240*240*120mm | |

| Extruding size | Round strip diameter≤ 30mm Rectangular block width≤35mm, height ≤20mm |

Packing width ≤ 200mm Packing height ≤ 60mm Packing length is no limited |

| Speed | 35-50 pcs /min(Exact capacity depends on your clay component and cutting length.) | |

| Power supply | 220v 60hz 25Kw | |

| Dimension | 15m*1.05m*1.4m | |

| Weight | 2730kg | |

Product Application