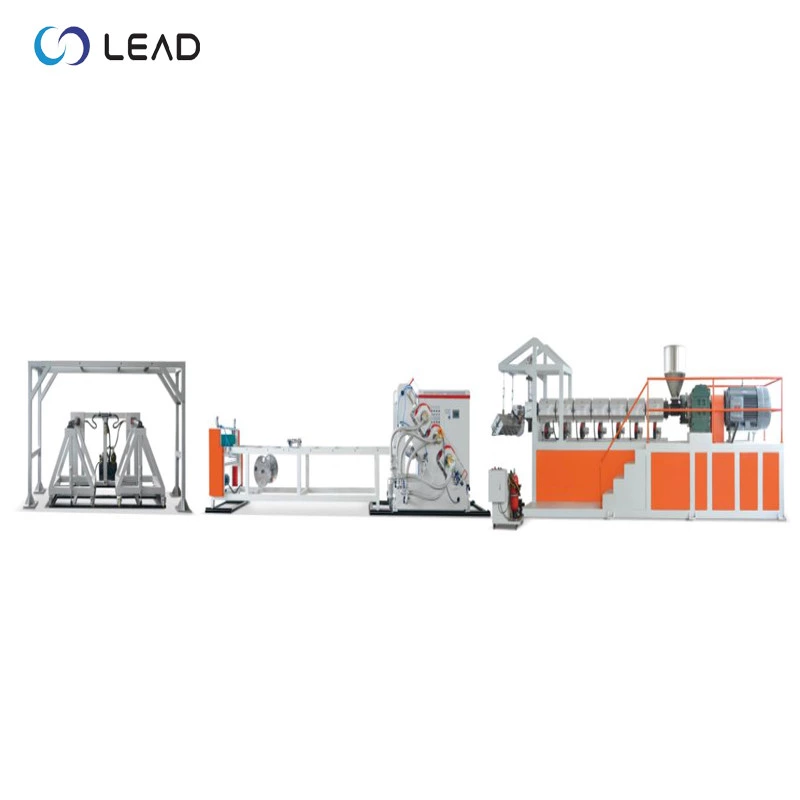

Sheet extruder

- MOQ:

- 1 set

- Payment:

- L/C,T/T

- Place of Origin:

- China

- Brand:

- LEAD

- Delivery Time:

- 7-20 days

Technical Features

1. The bracket is welded and formed by the national standard steel Q235-A

2. Edge trimming device: Two cutting knives are used on both sides to effectively correct edge material and segmentation, so that the sheet can reach the required width

3. The transition rollers are all wear-resistant aluminum guide rollers, and the surface is treated with hard oxygen.

4. Hydraulic oil motor large winding device, the winding diameter can reach 1.5m

5. This traction device adopts Φ190 neoprene rubber roller and steel roller, among which the steel roller is the driving roller, which is driven by chain, reducer, and the transmission power is 2.2kw

6. The bearing seat is made of 45# steel, and the structure is split, which is convenient for bearing replacement and maintenance

7. The roller is treated with intermediate frequency, the surface hardness of the roller is above HRc58, and the quenching depth is 3-5mm

8. The inner spiral liner improves the cooling effect

9. Roller gap adjustment method: worm and worm synchronous rise/fall adjustment

Technical Parameter

|

Press roller size |

Φ450×1000 |

|

Press roller size |

Φ450×1000 |

|

Cooling roller size |

Φ450×1000 |

|

Roller error |

≤0.01mm |

|

Roller roughness |

Ra0.025ʯm |

|

Motor power |

4kw |

|

Surface temperature of roller |

≤±1℃ |