Side seal shrink packaging machine

- Model:

- LD-SW550

- MOQ:

- 1 set

- Payment:

- L/C,T/T

- Place of Origin:

- China

- Brand:

- LEAD

- Delivery Time:

- 7-20 days

LD-SW Side seal shrink wrap machine

The machine picture(with a infeeding conveyor and collection conveyor, the infeed conveyor can be customized according to different product size.

Technical Features

1. Side seal can be cut continuously and uninterruptedly by constant temperature knife.

2. Horizontal seal adopts the form of constant temperature knife and lifting seal.

3. When the product size changes within the allowable range, it can be easily adjusted without changing any mould or fixture.

4. The length of the product can be automatically detected by two groups of electro-eyes in the horizontal or vertical direction. The length of the product is not limited, and the products of different lengths can be produced at the same time.

5. It is easy to operate and learn. Five groups of converters are used to control the transmission accurately.

6. Plexiglass safety door not only guarantees safety but also monitors production situation.

7. The rewinding waste edge film is controlled by separated motor. It prevent broken waste film when pulling&rewinding. And very easy to take apart the waste film roll.

Technical Parameter

Main technical parameters

| Model | BF-550 |

| Power Supply | 220V;50/60hz |

| power | 1.35kw |

| highest speed | 20-30 packs / min. |

| Packing height | ≤150mm |

| Packing width | ≤350mm |

| package size | Width + Height ≤500mm Unlimited length |

| Applicable film | POF folded film、PE membrane |

| Platform height | 780-850mm |

| Air pressure | 5KG/M² |

| Main material | Carbon steel |

| Weight | 300KG |

Shrink tunnel parameters

| Model | BS4525N shrink tunnel |

| Power Supply | 380v/50-60HZ/ 3Phase |

| power | 12KW |

| highest speed | 20-30packs / min. |

| Mechanical dimension | 1900×720×1350mm |

| Shrinkage tunnel inner size | 1500×450×250mm |

| Main material | Carbon steel |

| Weight | 130KG |

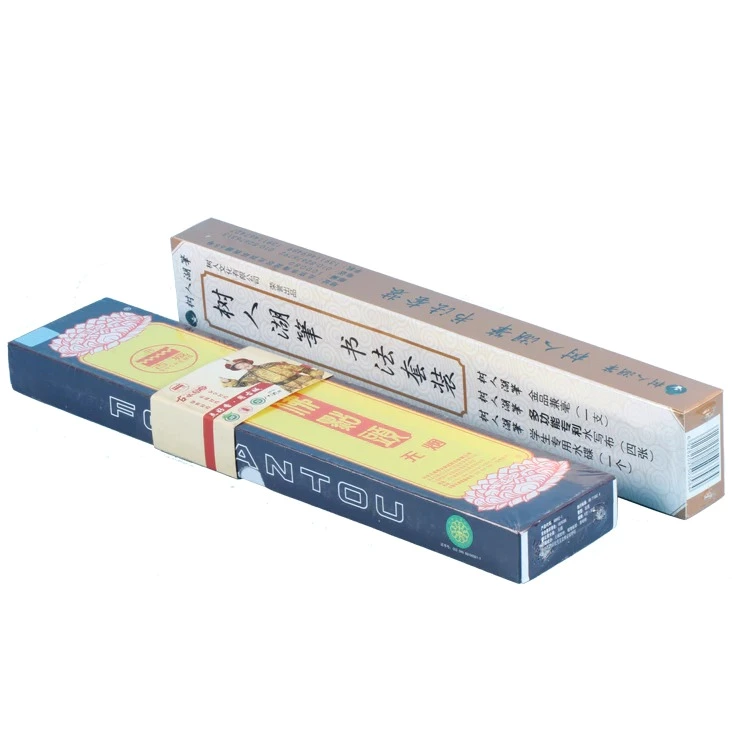

Product Application

Cardboard box packaging machine |

Photo frame packaging machine |

PP lunch box packaging machine |